In the varied industries that use bulk chemical solutions, maintaining optimal temperature conditions for the storage tanks that hold company chemicals is of paramount importance. A crucial part of this process involves the use of a specialized system known as heat tracing. This article provides an in-depth look at the use, reasons for use, and benefits of heat tracing for bulk chemical storage tanks.

Understanding Heat Tracing

Heat tracing, also known as heat tape or heating cable, is a system designed to provide internal heat to a liquid within a tank through conductive heat transfer. It maintains or raises the temperature of the stored material, ensuring that the product’s integrity is preserved. This technology is an important component of a comprehensive tank heat maintenance system, offering a flexible, adaptable, and efficient solution compatible with various sizes, types, and shapes of tanks and containers.

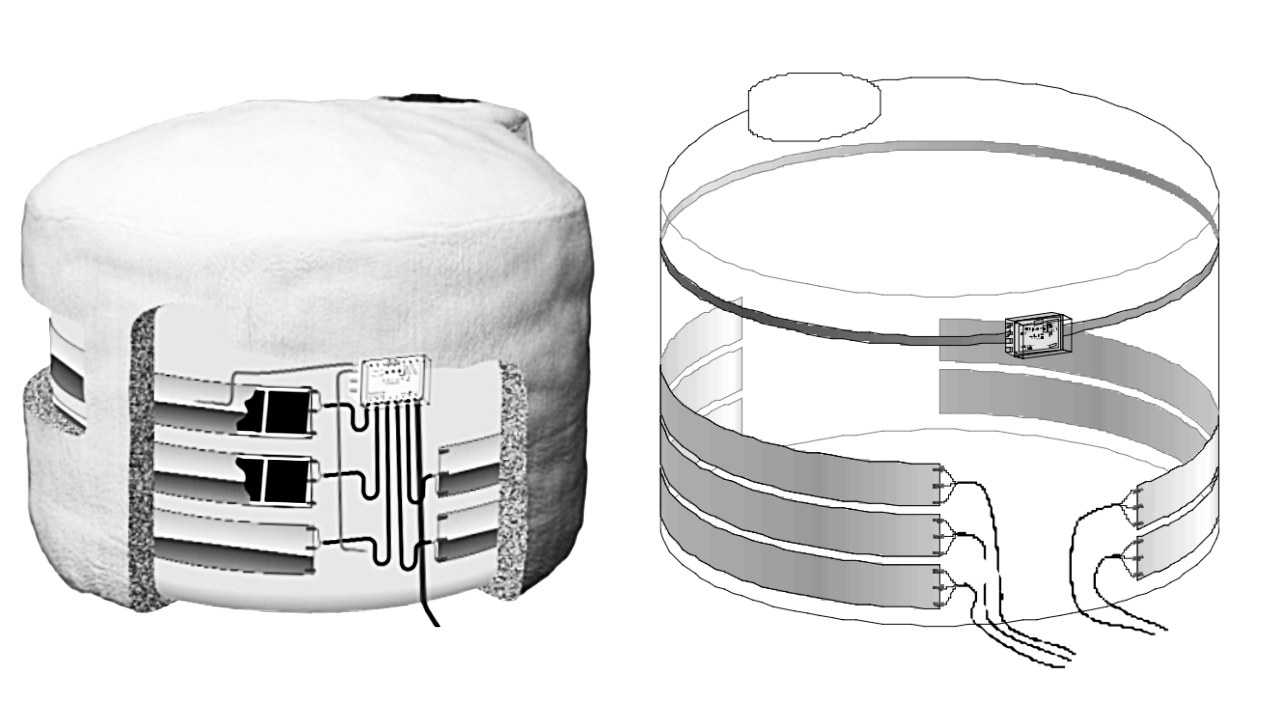

National Tank Outlet offers a Heat Tracing and Insulated System, which comprises heat tracing panels and an electronic control box to control the temperature setting. This system ensures temperature maintenance of stored liquids, not to exceed 100°F for polyethylene tanks, thereby preserving the quality and usability of the product over environmental conditions and fluctuations. Polyurethane insulation is optional but recommended.

Heat tracing systems and insulation is ideal for and widely used across modern industries and infrastructures including: the chemical processing industry, manufacturing, agriculture, water and wastewater treatment, automotive, industrial operations, petroleum refining and extraction, construction, and more.

The Benefits of Heat Tracing System Equipment

Bulk chemical storage tanks are often exposed to temperature fluctuations that can impact the quality and consistency of the chemicals stored in them. Using heat trace equipment is a must, as it helps maintain a steady temperature within the tank. It also helps prevent the chemicals from solidifying or becoming too viscous, which can create problems when pumping or transporting them. Proper temperature control with heat trace equipment minimizes the risk of spills and leaks, which can lead to significant environmental and safety hazards.

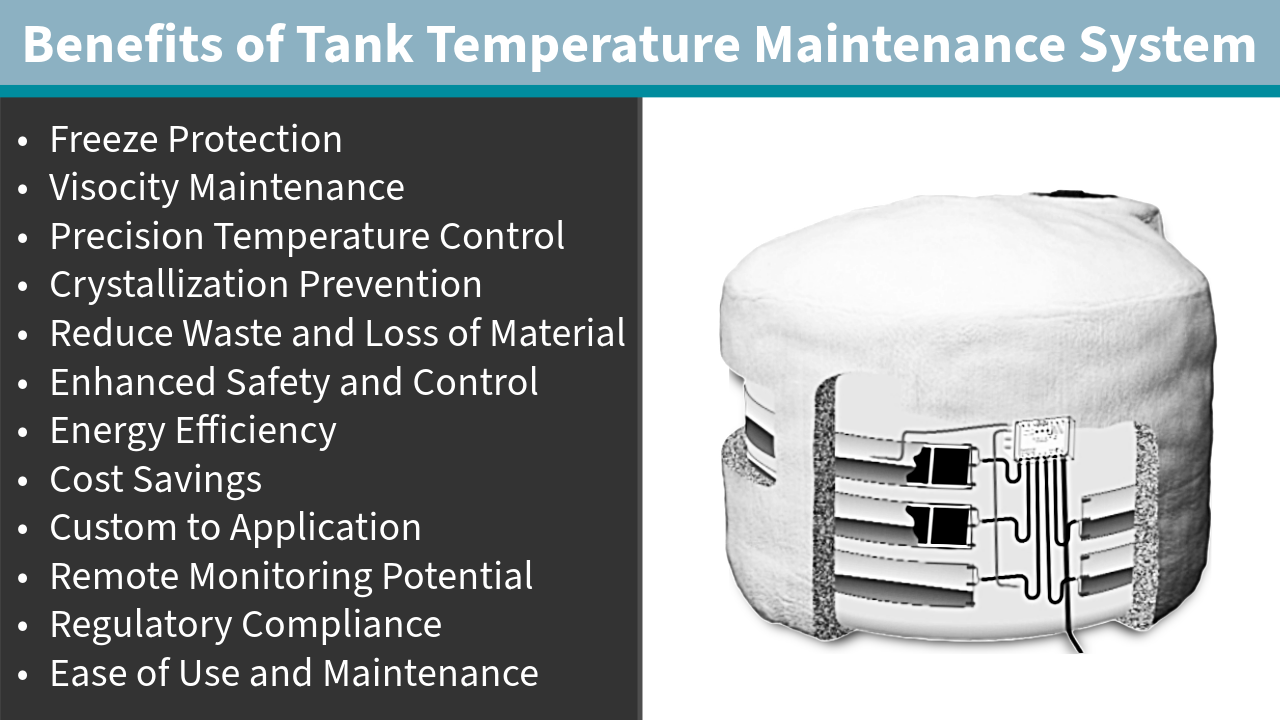

The use of heat tracing in maintaining the temperature of storage tanks offers numerous advantages:

1. Preventing Freezing and Maintaining Viscosity

One of the primary benefits of heat trace equipment for chemical storage tanks is its ability to prevent the contents from freezing. Chemicals can become viscous or solidify at low temperatures, causing operational problems. Heat trace systems ensure a consistent and appropriate temperature, maintaining the desired viscosity and preventing costly damage to equipment.

2. Precise Temperature Control

Heat tracing allows for accurate temperature regulation, ensuring that chemicals remain in their optimal state.

3. Crystallization or Solidification Prevention

Certain chemicals can crystallize or solidify if their temperature drops below a specific point. Heat tracing helps prevent this by maintaining a consistent temperature.

4. Reducing Material Waste

Accurate temperature control can significantly reduce material waste. When chemicals solidify or become too viscous, it can be challenging to remove or use them effectively. By maintaining the right temperature, heat trace equipment helps minimize waste and maximize the utility of stored chemicals.

5. Enhancing Safety

Safety is paramount when dealing with chemicals. Heat trace systems reduce the risk of accidents caused by temperature-related issues, which can lead to hazardous situations, especially when dealing with volatile chemicals. Preventing freezing or overheating helps maintain the stability of chemicals, reducing the chances of leaks, spills, or explosions.

6. Energy Efficiency

Modern heat trace systems are designed for energy efficiency. They use advanced technology, such as self-regulating cables, to minimize energy consumption. This not only lowers operational costs but also aligns with sustainability goals by reducing greenhouse gas emissions.

7. Cost Savings

Investing in heat trace equipment may initially seem costly, but it often pays off in the long run. By preventing damage to tanks and materials, ensuring uninterrupted workflow, as well as improving energy efficiency, these systems can lead to a significant return on investment over time.

8. Customized Solutions

Heat trace systems can be tailored to the specific needs of chemical storage tanks. Engineers can design solutions that fit the size, shape, and requirements of the tank, ensuring precise temperature control.

9. Remote Monitoring and Control

Many modern heat trace systems offer remote monitoring and control capabilities. This allows operators to adjust temperature settings or detect issues in real-time, enhancing overall control and safety.

10. Compliance with Regulations

Chemical storage facilities often need to comply with strict regulations regarding temperature control and safety. Heat trace equipment helps meet these regulatory requirements, reducing the risk of fines or shutdowns.

11. Ease of Use and Maintenance

Heat tracing systems are easy to use and require minimal maintenance, making them a practical solution for many industrial applications.

Reasons to Use Heat Tracing

There are many reasons why using heat trace equipment is crucial for bulk chemical storage tanks. One of the primary reasons is to maintain the viscosity of the chemicals stored in the tank. For instance, some chemicals can separate or turn solid when exposed to cold temperatures. If the chemical is allowed to solidify, it can result in damage to equipment, clogging in pipes, loss of product, and significant downtime while the issue is resolved.

Additionally, for some chemicals, if the temperature of the chemical gets too high, it can create a dangerous work scenario and pose a chemical hazard risk. By maintaining proper temperature with heat trace equipment, these issues can be prevented.

Heat tracing is a versatile solution, offering several reasons for its use in the chemical processing industry:

- Versatility: It can be used on various types of tanks, including vertical, horizontal, cone bottom, open top, and double walled tanks.

- Wide Range of Applications: Heat tracing is compatible with a broad range of chemicals, including acids, bases, solvents, and more.

- Regulatory Compliance: Heat tracing can help meet certain regulatory requirements related to temperature control in chemical storage

Types of Tanks Suitable for Heat Tracing

National Tank Outlet’s heat trace and insulation system is suitable for a variety of tanks used in the chemical processing industry. We can heat trace and insulate vertical tanks up to 15,000-gallon size and double-wall tanks from 35 to 12,500 gallons. The quantity and type of panels required are determined by the size of the tank, desired temperature maintenance, and environmental conditions.

Types Of Chemical Tanks Heat Trace Equipment Is Good For

Heat trace equipment can be used for various types of chemical storage tanks depending on their design, volume, and purpose. Some of the common types of tanks that can benefit from heat tracing are:

- Polyethylene Tanks: As these tanks have excellent chemical resistance, they are often used for storing aggressive chemicals. Heat tracing can help maintain the optimal temperature of these chemicals.

- Stainless Steel Tanks: Known for their durability and resistance to corrosion, these tanks are ideal for heat tracing, which can further enhance their efficiency.

- Fiberglass Tanks: These tanks are known for their strength and longevity. Heat tracing can be easily applied to these tanks to provide consistent temperature control.

- Jacketed tanks: Tanks that have a double-wall construction, with an inner tank containing the chemical and an outer jacket that can be heated or cooled using heat tracing. Double walled tanks are widely used in the chemical industry for safety and meeting secondary containment regulations.

- Insulated tanks: Tanks that are insulated to prevent heat loss or gain. Heat trace equipment can be used to maintain the temperature inside the tank irrespective of the external conditions. These tanks are commonly used for storing chemicals that require specific temperature conditions, such as food-grade products or heat-sensitive chemicals.

Poly Tank Insulation | A Complement to Heat Tracing

Poly tank insulation is an effective complement to heat tracing for maintaining temperature-sensitive substances in industrial chemical storage tanks. Recognizing the importance of adequate temperature control in industrial processes, many companies opt for polyurethane insulation.

Poly tank insulation maintains product quality by reducing heat loss, improving energy efficiency, and reducing maintenance costs. It is a cost-effective and energy-efficient solution, especially in harsh environments with fluctuating temperatures. By combining polyurethane insulation and heat tracing, industries can guarantee high-performance performance, product integrity, and safety.

Polyurethane insulation offers a temperature maintenance upgrade and customization choice for polyethylene storage tanks. It complements heat trace equipment to regulate liquid chemical temperature effectively. When combined, poly tank insulation and heat equipment provide a reliable option to keep company chemicals stable, secure, and at the necessary temperatures.

To safeguard a company stock solution and maintain consistent storage temperature, opt for an insulated poly tank equipped with a custom-engineered heat tracing system. This system meets all application specification requirements, including desired temperature, chemical material to be stored, and total volume.

Tank Insulation Specs

Insulation used is a polyurethane foam with a density of 2.0 – 3.0 lb./ft3 with an “R” value of 8.33/in. The foam is applied with a nominal thickness of 2″ to all external tank surfaces except the tank bottom shell. Upon completion of application and curing of the insulation, two full coverage coats of latex mastic coating are applied to the surface of the insulation in such a manner as to seal the insulation from the outside environment. The latex mastic can be ordered in gray (standard) or white in color.

Read our post Poly Tank Insulation for Regulating Chemical Storage Temperature for more information.

Bulk Chemical Solutions Benefiting from Heat Tracing

Several bulk chemical solutions can benefit from heat tracing:

- Acids and Bases: Acids and bases, such as sulfuric acid and sodium hydroxide, often require specific temperatures to prevent degradation or changes in concentration.

- Solvents: Certain solvents, like toluene and xylene, need to be kept at specific temperatures to prevent condensation or evaporation.

- Petrochemicals: Petrochemicals, such as benzene and ethylene, can benefit from heat tracing to maintain their fluidity and prevent solidification.

- Molasses and Syrups: These products are highly viscous and can solidify or crystalize if they’re stored at low temperatures. Heat tracing can keep them at the proper temperature and prevent them from seizing up.

- Caustic Soda and Other Chemicals: These products are highly corrosive and can damage the tank material if they’re stored at high temperatures. Heat tracing can prevent them from reaching temperatures that can cause corrosion or degradation.

- Water-based Solutions: Water-based solutions, such as antifreeze or glycol solutions, can freeze if exposed to low temperatures. Heat tracing can prevent them from solidifying and blocking the pipelines or the tank.

The following is a list of specific liquids and chemicals commonly used with heat trace equipment and/or polyurethane tank insulation:

- Aluminum Sulfate (Alum, Al2(SO4)3)

- Ferrous Sulfate (Iron (II) Sulfate)

- Hydrochloric Acid (Muriatic Acid, HCl)

- Hydrofluosilicic Acid (Fluorosilicic Acid, H2SiF6)

- Potassium Hydroxide (Potash, KOH)

- Sodium Aluminate (Sodium Aluminum Oxide, NaAlO2)

- Sodium Bisulfate (Sodium Hydrogen Sulfate, NaHSO4)

- Sodium Hydroxide (Caustic, Lye, NaOH)

- Sodium Hypochlorite (Bleach, NaOCl)

- Sodium Permanganate (Sodium Manganate (VII), NaMnO4)

- Sulfuric Acid (Dihydrogen Sulfate, Battery Acid, H2SO4)

- Surfactants

- Urea Solutions (Carbamide, CH4N2O)

- Water

Heat Tracing and Insulation Specs and Overview

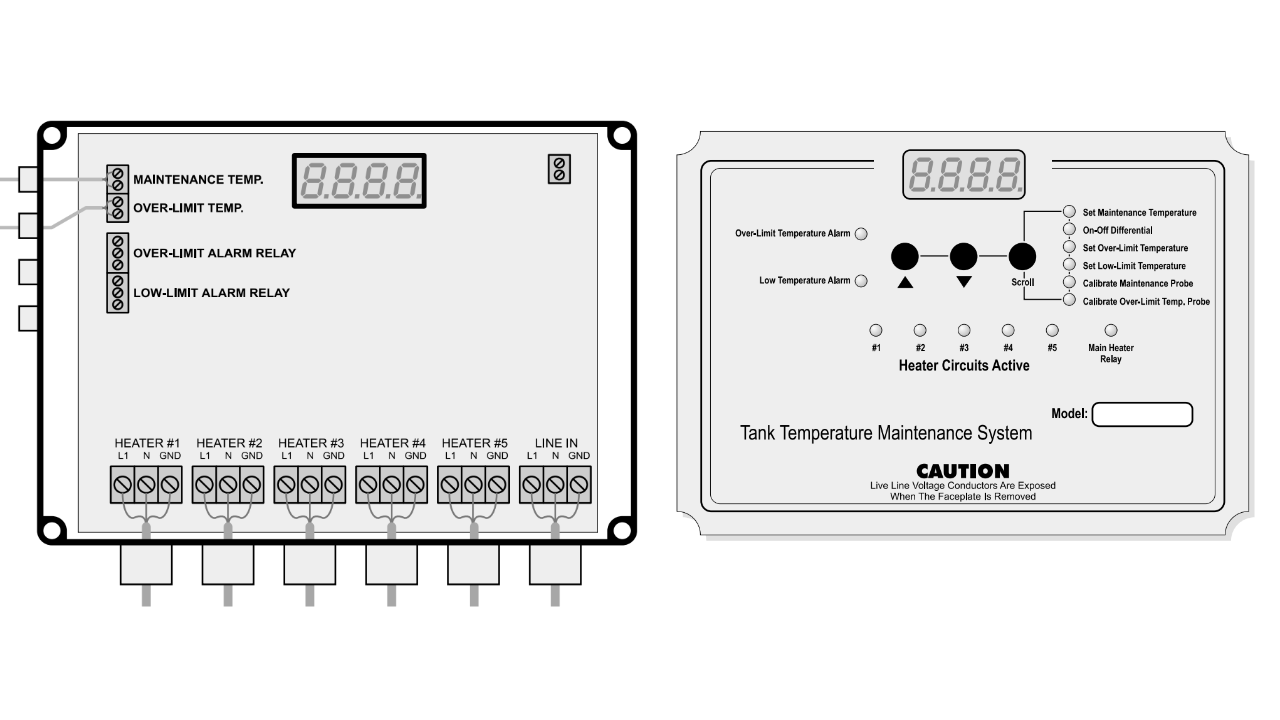

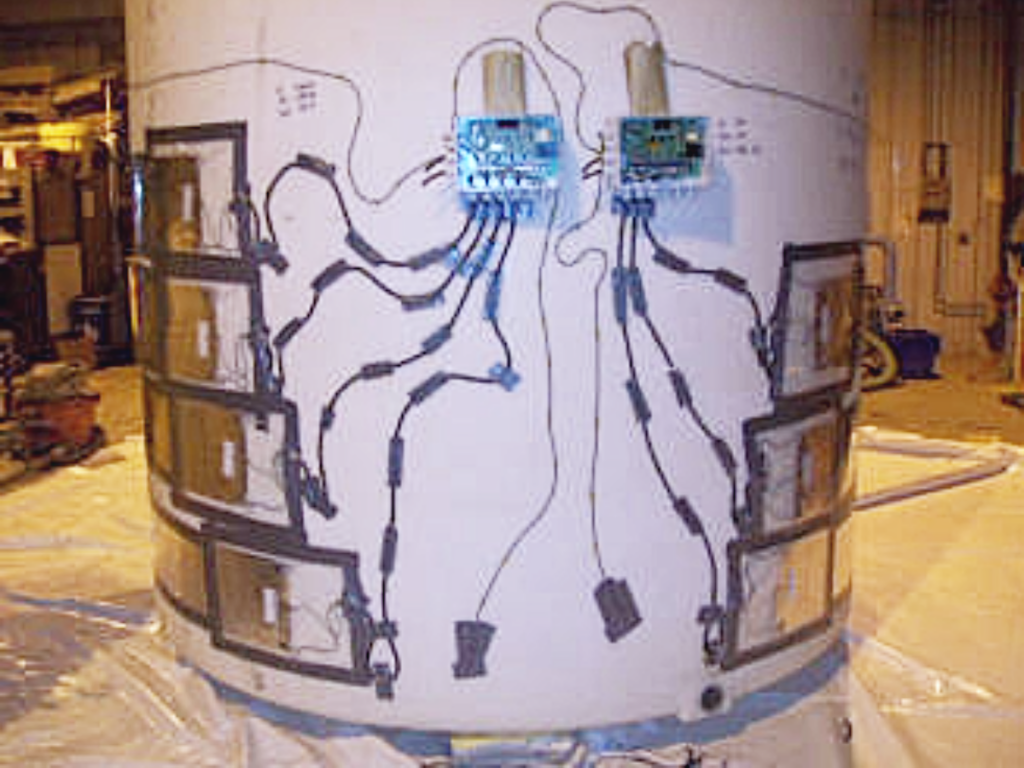

Heat tracing equipment will include a Nema 4X rated weatherproof control box, 110 V AC electrical cables and components, and conductive heating panels pre-configured for maintaining the required temperature based on customer provided specifications. The number and type of panels needed are determined by the tank size, desired temperature maintenance, and environmental conditions.

Standard heating systems are available with a delta-T range of 40°F, 50°F, 60°F, 70°F, 80°F, 90°F, and 100°F. The delta-T represents the difference between the desired temperature and the minimum ambient temperature range expected.

- Nema 4X rated, pre-wired 110 VAC control box mounted in weatherproof, gasketed, impact resistant plastic

- Electrical wiring diagram in control box

- Heating panels with 0.022 watts/cm2 maximum heating density, quantity dependent on application requirements

- Range of delta-T options: 40, 50, 60, 70, 80, 90 and 100

- Two temperature controls: one for maintenance temp and one for high temp settings

- Power off failure fault mode

- Ideal for use with polyurethane tank insulation

Summary | What This All Means for You

- Essential Temperature Control: Heat tracing ensures your stored chemicals maintain optimal temperatures, preventing freezing, solidification, or overheating.

- Enhanced Safety: Reduces risks like leaks, spills, and hazardous reactions caused by temperature fluctuations.

- Improved Efficiency: Keeps chemicals in their usable state, minimizing waste and preventing workflow disruptions.

- Energy Efficient: Modern systems use advanced technology to conserve energy and lower operational costs.

- Regulatory Compliance: Helps meet industry standards for temperature control and chemical safety.

- Custom Solutions: Heat tracing can be tailored to the specific requirements of your storage tanks and applications.

- Reduced Maintenance: Offers reliable performance with minimal upkeep for long-term operations.

- Integration with Insulation: Pairs seamlessly with polyurethane insulation to maximize temperature stability and energy savings.

- Broad Compatibility: Applicable to various tank types and chemicals, making it a versatile solution for industrial needs.

- Cost-effective: Prevents costly damage, downtime, and safety hazards, offering significant ROI over time.

Takeaway | Heat Tracing for the Ultimate in Storage Temperature Maintenance

In conclusion, heat tracing provides an efficient, reliable, and cost-effective solution for maintaining the temperature of bulk chemical storage tanks. It not only ensures the quality, stability, and safety of chemical products and the tanks that hold them but also improves their efficiency and lifespan. By keeping the temperatures at the right level, heat tracing equipment prevents costly product loss, downtime of company workflow and systems, can reduce operational bottlenecks and safety hazards. Heat tracing and thermal insulation brings numerous benefits from precise temperature control to enhanced safety, making it an essential component in industrial tank temperature maintenance.

With National Tank Outlet, America’s Liquid Tank Superstore, industry professionals who handle, process, and synthesize chemical products can access quality, reliable, and customizable heat trace equipment solutions that meet their specific needs. Our team of experts is ready to guide you through the selection process to ensure you get the best solution for your application. Don’t compromise on the quality and safety of your chemical storage – invest in heat trace equipment today.

To learn more about our products and services, contact us today to learn how we can help you achieve optimal performance and safety in your operations.

Heat Trace Systems for Chemical Storage