How do you choose the right custom storage tank for your specific needs from all the stock products and options available? And when is a custom storage tank the best choice? With numerous variables to consider, the key factors that influence the decision are the types of chemicals being stored and the workflow needs of the tank system. And understand — selecting the right storage tank is vital for safety and achieving the most optimal, most effective results.

A custom tank is a smart choice for liquid handling applications that need: (1) specialized access, (2) a specialized shape, and/or (3) specialized features or control components for functionality.

At the National Tank Outlet, we specialize in designing and fabricating custom polypropylene tanks and process systems tailored according to our client’s specs and job requirements. In this blog, we’ll guide you through the consideration points as you move towards choosing the best option for your application.

Here’s a take on what we’ll look at:

- Understand Your Application: How the purpose of your storage impacts everything from tank material to design.

- Explore Material Compatibility: The role of polypropylene and various components in safely handling different chemicals and conditions.

- Discover Customization Options: How custom features can maximize performance and fit your exact needs.

- Highlight Key Tank Systems: A closer look at our most common and versatile tank options.

Whether you’re managing chemical processes, looking for specialized rinse tanks, or something entirely original, this guide will simplify your decision making process and help point you in the right direction.

Understand Your Application

The Importance of Knowing Your Cargo

Selecting the right storage tank begins with a thorough understanding of what you’re storing. The specific properties and safety requirements of your chemicals, mixtures, and raw materials need to be your top priority. Factors like chemical reactivity, temperature tolerances, personnel hazard, volatility and fume generation all play an important role in determining what storage solution will be best.

For example:

- Highly volatile chemicals may require tanks with integrated vapor management features such as a fume scrubber.

- Aggressive chemicals may require more specialized fittings such as CPVC, PVDF, or stainless steel.

- Solutions prone to separation or that need mixing may benefit from a circulation or agitation setup.

- Liquids with high leak risk or environmental concern may require additional containment or safety measures.

- Materials sensitive to high heat might need insulation to maintain temperature control.

- Materials sensitive to low temperatures may need thermal control units.

Without properly evaluating the characteristics of your cargo, you risk compromising safety, efficiency, and long term performance.

Defining Your System’s Functional Needs

Once you’ve identified the properties of your cargo, it’s time to think about how the tank system will need to function. Every application and worksite has unique demands, and your tank should be designed to meet them. Consider the following questions when planning the specs of your custom tank:

- Does your workflow process require multiple interconnected tanks, a single tank with multiple connection points, or a modular tank with multiple tanks built in?

- Will you need overflow management, discharge capabilities, or secondary containment?

- How important is accessibility? Do you require easy-to-remove lids, custom access ports, an open top, a set height, or liquid flow controls?

- Will the application need or benefit from mobility, fume control, or temperature management?

Industries like electropolishing and chemical manufacturing often rely on specialized systems. Electropolishing operations might need uniquely sized tanks designed for electrolyte handling with overflow capabilities, while chemical manufacturing may demand highly corrosion resistant tanks with selective fittings for liquid handling, fume management for vapors, or with mixers for production.

The bottom line: your custom tank setup should work seamlessly within your specific workflows to deliver the best, most reliable results.

Build Materials for Polypropylene Tanks

Why Polypropylene Is an Ideal Choice

Polypropylene is one of the most versatile materials for customized storage tank systems, making it a popular choice for many industries. Known for its widespread chemical compatibility, polypropylene can safely store many alkaline solutions, acids, and other corrosive or potentially dangerous solutions. Polypropylene is lightweight and offers excellent physical durability and stress tolerance to deliver long term performance. The material also has a high temperature rating (180°F, continuous), abrasion resistance, great cleanability, and food safe properties.

For example, polypropylene is commonly used to store chemicals like sodium hydroxide, hydrochloric acid, phosphoric acid and sulfuric acid mixtures, and various detergents because it maintains its integrity without corroding. Its unique properties make it ideal for demanding industrial applications where reliability and chemical stability are essential.

The Value of Custom Fabrication

Customization plays a primary role in achieving optimal performance with a personal polypropylene storage tank. At NTO Tank, we offer made-to-order fabrication products custom built by our expert team according to your exact specifications and needs — whether that involves cutting, welding, plumbing, or creating original, asymmetrical tanks.

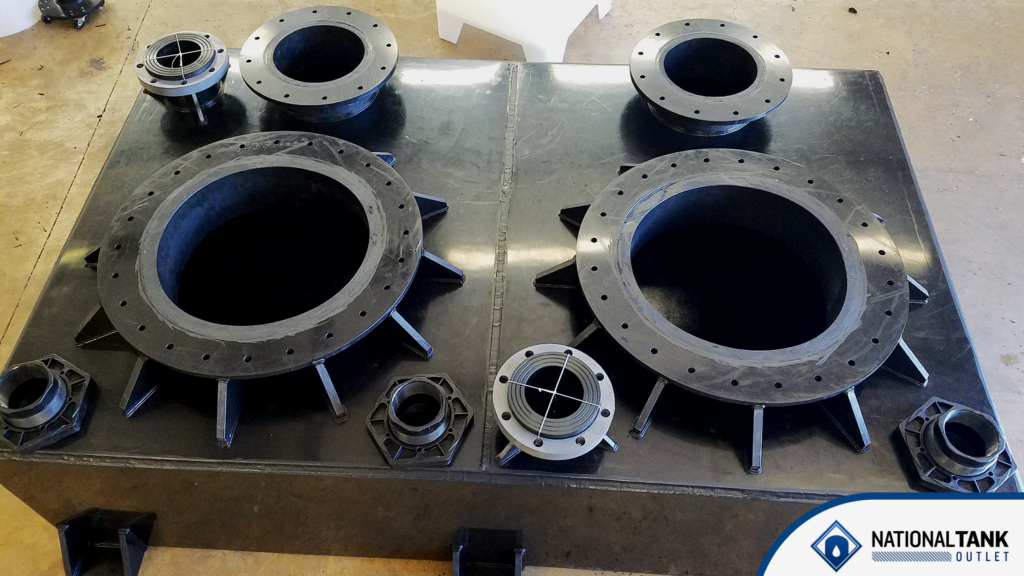

Customization goes beyond just the tank body. Chemical compatibility must be ensured at every level of the system, including fittings, gaskets, sensors, and plumbing connections including bulkheads, pipes, valves, and pumps. By accurately addressing each component, we can work together to achieve a tank system that not only fits your working application but also improves overall capability and safety.

To match the application and liquid compatibility, we offer a full range of component types and construction materials.

Whether you need a seamless, single piece tank or a complex multi tank setup — or a fully rigged, ready to go system — polypropylene’s adaptability and our pro staff allow for nearly endless possibilities in design and the capability to turn that design into reality.

Custom Polypropylene Tank Options Examples

When it comes to custom polypropylene tanks, there is no one-size-fits-all solution, and that’s the point. At the National Tank Outlet, we specialize in offering one of the market’s most comprehensive range of options so we can meet the unique needs of not just a few but many of today’s hardworking, high throughput industries and applications. From process tanks to specialty treatment systems, each tank is meticulously built for accuracy and performance.

Below are some examples of common custom polypropylene tank options our clients have requested.

Process Tank Systems

For industries focused on plating, anodizing, or processing materials, process tank systems are essential. These tanks are designed to handle demanding workflows such as chemical reactions, surface treating metals, or processing delicate components.

One of the key features of process tank systems is the ability to integrate multiple tanks into a streamlined system for applications with multiple steps. Interconnected or multistep tanks simplify complex workflows and allow seamless transitions between stages like cleaning, coating, and rinsing. This setup not only saves time but also ensures greater precision, consistency, and results.

Specialized Tanks for Industry Applications

Electropolishing Tanks

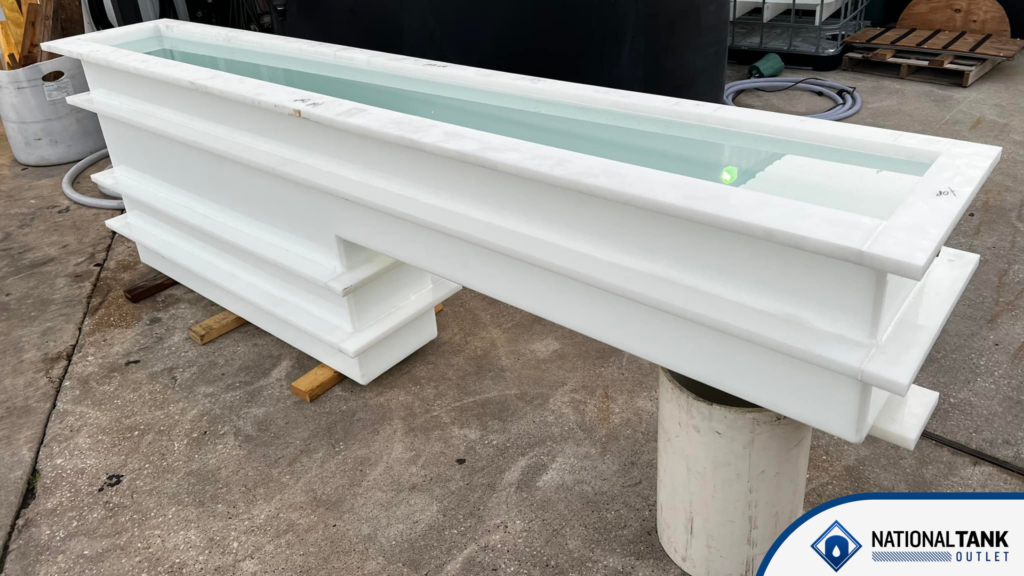

Electropolishing tanks are made to achieve flawless surface finishes on metals. These tanks are built with the durability to handle electrolytes and the accessibility to easily treat metal items in a business’s polishing applications.

Alkaline Wash Tanks

Designed for manufacturing environments, alkaline wash tanks provide a reliable solution for cleaning and degreasing. The tank’s chemical compatibility ensures it can withstand commonly used, harsh cleaning agents without being damaged.

Rinse Tanks

When a repetitive rinse process is part of your workflow, rinse tanks are the perfect fit. Built to handle repeated use without containment concerns, they are ideal for businesses that need clean rinsing solutions to prepare materials for the next step.

Tanks for Chemical Stability

Chemical Manufacturing Tanks

Precision, versatility, and adaptability are critical in chemical manufacturing due to the variety of liquids and workflow needs. Custom chemical tanks are engineered to match the compatibility requirements of your materials and working conditions while ensuring safety and product stability.

Acid Neutralization Tanks

Managing acidic cargo or waste often needs a specialized solution. Acid neutralization tanks can be used to balance acidity and neutralize acidic waste or byproducts to a point that is safe for handling or disposal.

Aluminum Deoxidizer Tanks

For industrial processes involving aluminum preparation or refurbishing, aluminum deoxidizer tanks provide the perfect setup for oxidation removal baths by being custom sized with the right shape, depth, and height.

Specialty Treatment Tanks

Alodine Treatment Tanks

Alodine treatment tanks are an excellent option for metal treatment activities that require superior corrosion resistance. They can be specifically designed to handle chemical baths for treating metals, equipment, and components to offer long lasting protection.

Containment Tanks

Safety is always a priority in industrial applications, especially when dealing with hazardous materials. Containment tanks act as a secondary barrier or basin, offering an extra layer of protection to prevent leaks or spills from reaching and damaging your facility, workers, or the environment.

These examples showcase a small set of the possibilities with custom polypropylene tanks. Whether your needs involve managing chemical reactions, enhancing workflows, or safeguarding your materials, custom made tanks from the National Tank Outlet are built for results.

Designing Your Perfect Customized Tank

Creating a customized tank that perfectly supports your operations starts with thoughtful design. From the layout of your work site to the specific features your process demands, every detail matters when optimizing performance and functionality.

Here’s what to consider when planning your ideal setup:

The Impact of Space and Tank Design

The configuration of your custom tank should work with your available space and existing equipment, not against it. Consider your floor plan to properly size the tanks to fit within the confines of your facility without disrupting workflows or needing extensive reconfiguration. For example, if space is limited, tanks that are more vertical or long can save room, while cylindrical tanks may be more suitable for open areas.

Tank shape and system design also play a large role in ease of use. An organized layout that aligns with your operations can make all the difference. Strategically designed and positioned tanks can streamline workflows and reduce bottlenecks. Also, plan for accessibility by ensuring valves and connections are easy to reach for setting up the new tank, daily operations, and regular maintenance.

Size and Capacity to Match Usage

Custom polypropylene tanks can be built in a full range of sizes and storage capacities. Request a tank with the volume to match your usage, from a few gallons to a thousand gallons or more.

Add Value with Specialized Features

To maximize functionality, add specialized features that match your specific application. For example:

- Sloped bottoms or integrated drains to promote complete discharge, prevent residue buildup, and simplify cleaning procedures.

- Multi-point connections, bulkheads, for versatile processes with different types of incoming and outgoing liquids, or the same liquid going multiple places, all managed within a single system.

- Complete, ready to go plumbing system with fittings, valves, piping, pumps, gauges, flow meters, and sensors.

- Open or closed tank system with or without lid, and with the lid type or style that best suits the workflow.

- Full air handling or fume scrubber systems, standalone or tank-integrated, for managing volatile liquids.

- Tank equipment harnesses for mounting external tools or machinery such as mixers, pumps, and meters.

- Multi-chambered tanks for housing different liquids used in different steps.

- Tank insulation to combat the effects of ambient temperature fluctuations for sensitive materials or applications.

- Induction heat transfer and tracing system for indirect liquid heating.

- Tank level sensors for continuous real-time monitoring of current liquid levels.

- Leak detection sensors for alert notification in the event of a tank leak or other failure.

Why Choose the National Tank Outlet for Your Custom Storage Solution?

When it comes to finding the perfect customized storage solution and working with an experienced partner willing to work alongside you, the National Tank Outlet stands out as one among the top in the industry. Here’s why we’re a go-to choice for custom built polypropylene tanks:

Extensive Custom Fabrication Options

We take pride in offering a wide range of polypropylene tank fabrication options with the knowledge and ability to execute the unique demands of each client. Whether you need a specialized shape, multi-tank system, or precise dimensions, our tanks are made to order.

Expertise Backed by Years of Experience

With years of proven expertise in fabricating and providing solutions, we understand the challenges specific industries face. We’ve worked alongside clients in some of the most demanding fields to create storage solutions that deliver on reliability and functionality. Our experience makes us confident that we can tackle complex requirements and provide long lasting results.

Reliable Guidance from Our Specialists

At the National Tank Outlet, client satisfaction begins with understanding your needs. Our team of specialists works closely with you to provide guidance and understand your needs, so every component is fully compatible with the chemicals and jobs you manage. By focusing on your objectives, we work to create a solution that maximizes functionality, safety, and value.

Takeaway

Choosing the right customized storage tank system benefits from a thorough understanding of your specific needs, selecting the best materials and components for your application, and exploring solutions designed to optimize performance. At the National Tank Outlet, we combine technical expertise, advanced customization capabilities, and unparalleled client support to deliver storage systems you can trust.

Contact our team today to discuss your application and discover how our custom polypropylene storage tanks can elevate your operations. Together, we’ll engineer a system that meets your needs.