There are several methods available to turn rainwater into potable, drinkable water that is safe to drink. By definition, potable water is water that is safe for human consumption as well as for use in other potable applications such as cleaning, cooking, and bathing. One of the most common reasons to treat harvested rainwater into drinking water is to use the water indoors and when no other water source or suitable water source is nearby. Other common uses for purified rainwater include drinking water for livestock, water for equipment operation, supply water for irrigation systems, and to serve as an emergency backup water supply.

In this Rain Tanks Series post, we will provide a detailed overview of the different methods recommended for treating rainwater into safe, drinkable, potable grade water.

Why Is Rainwater Not Safe to Drink?

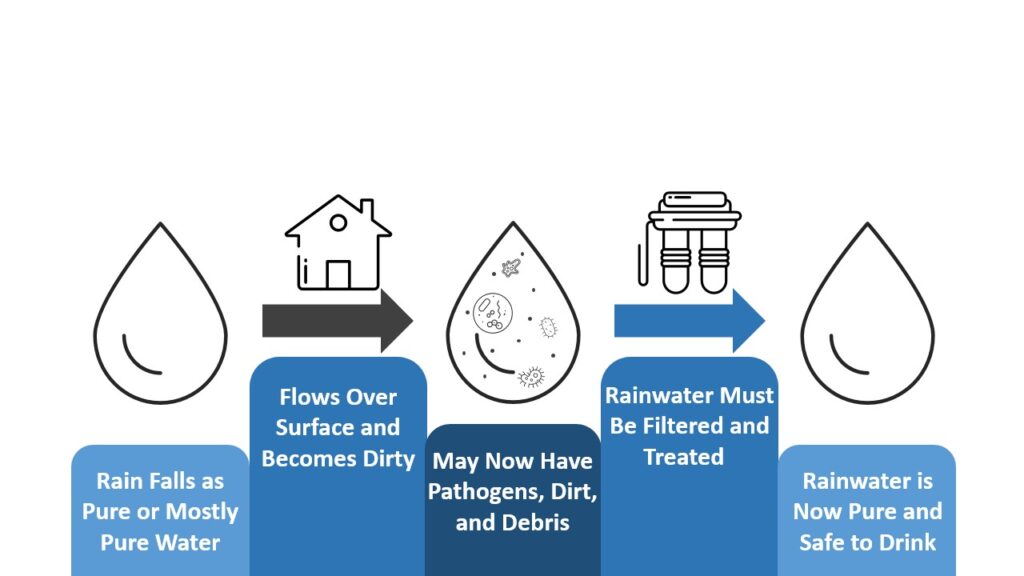

First, why is harvested rainwater considered not safe to drink? Without the proper treatment, rainwater collected through rainwater harvesting practice is not recommended for potable water applications. This is due to contamination by impurities and pathogens potentially within rainwater as it falls and flows over surfaces to the collection container. The term “pathogen” refers to microbiological organisms and viruses that can cause illness. Pathogens most often make their way into a rainwater container through animal activity and fecal matter on the rain catchment surface. Common microbiological pathogens can include various bacteria, parasites, and their cysts. For more on this, see our post Why Should I Not Drink Rainwater (Before Treating It).

With the proper rainwater harvesting system and treatment, rainwater can be used for drinking as well as other indoor potable and non-potable applications. A significant amount of water can be collected through rainwater harvesting practice and with the right setup, can potentially supply all the water needed. Don’t believe us or skeptical? Consider our review of How Much Rainwater Can I Collect with Rainwater Harvesting with many examples and a state-by-state look at average rainfall amounts to show just how much water can be supplied through rainwater harvesting.

Of note, there are also regulations in some U.S. states that prohibit rainwater for indoor potable uses. Locations that do allow it will require a proper and effective setup. The same is also true for indoor non-potable uses such as flushing toilets because, even though it is defined as a non-potable use, potable grade or near-potable grade water is still required.

Initial Basics

Prior to treating the rainwater, there are two initial basics that should be considered for all rainwater harvesting systems intended to provide drinking water. First, use an ANSI/NSF 61 certified rainwater collection tank to capture and hold harvested rainwater. An ANSI/NSF 61 container has been independently certified to comply with U.S. health and safety standards to provide and be in long-term contact with drinking water. Second, use pre-tank rain harvesting accessories to prevent any larger debris (e.g., sticks, leaves, seeds) from reaching the collection container and that could cause clogs in a water pump, filter, or equipment.

Available Methods for Treating Harvested Rainwater

With the current level of technology and knowledge available at the time of this writing, there are two (2) main methods recommended for treating harvested rainwater. Main rainwater treatment options include ultraviolet (UV) light and chemical treatment. Additional options include reverse osmosis and ozone gas, also known as ozonation. These last options are better reserved for specific use cases and may be suitable as an alternative choice. Harvested rainwater can also be boiled to make it safe for drinking; however, this is mostly suited to emergency type situations and not for setups intended as long term, repeat use systems.

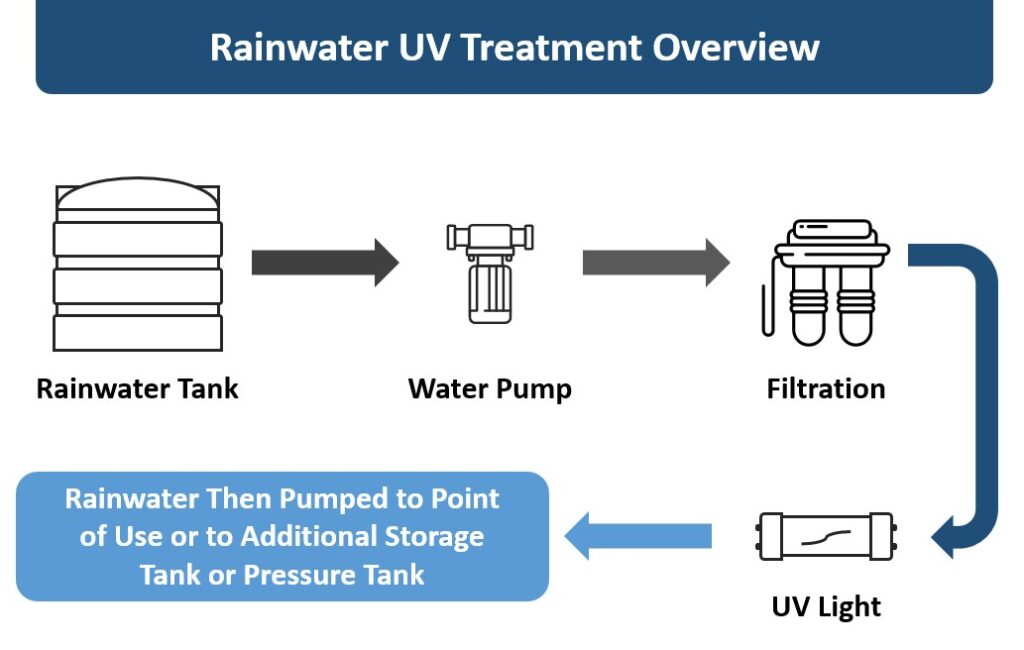

It is important to note that a water pump will be required for UV light treatment and reverse osmosis if the rainwater system and intended use isn’t already set up to include one.

Ultraviolet (UV) Light Treatment

Ultraviolet (UV) light treatment is a top recommended method for rainwater harvesting systems to purify collected rainwater into safe, potable grade water. UV treatment is also a preferred method as it is effective, efficient, easy to use, and easy to maintain. Additionally, UV light systems do not require a chemical to be added to the rainwater collection tank, which often involves measuring or dosing equipment setup as well as buying, storing and handling the chemical.

Consider:

- U.S. Office of Energy Efficiency & Renewable Energy | Water-Efficient Technology Opportunity: Rainwater Harvesting Systems

- Ohio State DNR | Continuous Disinfection for Private Water Systems

- The U.S. CDC | A Guide to Drinking Water Treatment Technologies for Household Use

How Does UV Light Treatment Work

An ultraviolet light rainwater treatment system works by using a UV emitting light bulb to expose pathogens in the water to high levels of high energy light waves that belong to the ultraviolet range of the electromagnetic spectrum. These light waves are high intensity and high strength. When pathogens are exposed to the UV light waves, the process is called UV irradiation. After successful irradiation, pathogens are considered inactivated. An inactivated pathogen is no longer able to replicate and becomes unable to cause disease since replication is a requirement for pathogen-based infection. UV light treatment does not kill or destroy pathogens but renders them harmless and no longer dangerous.

Requirements for UV Light Systems

Ultraviolet light treatment provides a paired benefit of requiring cartridge filtration for the removal of sediments and other particles that are too small for removal by pre-tank filter accessories such as a leaf eater and tank screen, which should still be used. While this is an additional piece of equipment and cost, (although some UV treatment systems include cartridge filters), the requirement of cartridge filtration will improve the total quality of the treated rainwater. A cartridge filter will remove suspended and dissolved materials, improve clarity, reduce turbidity and odors, remove some larger sized pathogens and cysts, and prepare the rainwater for UV treatment.

Why Filtration is Required

Filtered, non-turbid water is a requirement for UV light treatment systems and for them to provide effective purification. As mentioned, UV light treatment exposes pathogens to intense levels of high energy light waves. The light waves must be able to contact the pathogens for a set amount of time depending on the strength rating of the UV bulb. If the rainwater to be treated is too cloudy and/or riddled with sediment, then it becomes possible for pathogens to make it through the UV chamber and not be properly irradiated, inactivated, and rendered harmless. This is why filtered non-turbid water is required.

Recommendations and Standards for UV Light Treatment Units

For a rainwater harvesting UV light treatment system, units are recommended to be a Class A system rated with a 40 mJ/cm2 UV output strength or capable of meeting this output with slower system flow rates. The 40mJ/cm2 UV output strength is a minimum threshold recommended by the U.S EPA for ultraviolet light treatment units to be reliably effective in pathogen inactivation. Rainwater harvesting UV light treatment units are also recommended to be certified by the American National Sanitation Institute (ANSI) and the National Sanitation Foundation (NSF). UV units should be certified to ANSI/NSF Standard 55. The 40 mJ/cm2 threshold is also the required limit for ANSI/NSF certification as a Class A UV system.

Recommendations and Standards for Rainwater Filtration

For rainwater harvesting filtration setup, a multistage filtration unit type product is recommended. Minimum filtration is at least a sediment cartridge style filter with a pore size rating of 3 to 5 microns. The best suited and recommended filter unit will include a larger pore size sediment filter to remove larger impurities, followed by a 3 to 5 micron pore size cartridge filter, and will also include an activated carbon filter to improve odors, taste, and to remove some dissolved chemicals that may be present. Independent cartridge filtration units are recommended to be certified to ANSI/NSF Standard 53 requirements.

Components of a Rainwater UV Light System

Rainwater UV light treatment systems are electrically powered products and will require a power source. Systems are composed of a UV light chamber, often made of stainless steel, that houses the UV emitting light bulb, sometimes also called a UV lamp, and plumbing ports for making connections to pipes. Many UV systems also feature a built-in cartridge filter or filters. The UV bulb will be rated with a set maximum output strength and run time in hours known as the life of the lamp. Common UV lamp life run times range from 3000 hours to 9000 hours. Many systems include maintenance lights that indicate when it is time to change a UV lamp. Proper maintenance and timely replacement of UV lamps is important to their proper function and effective disinfection of rainwater.

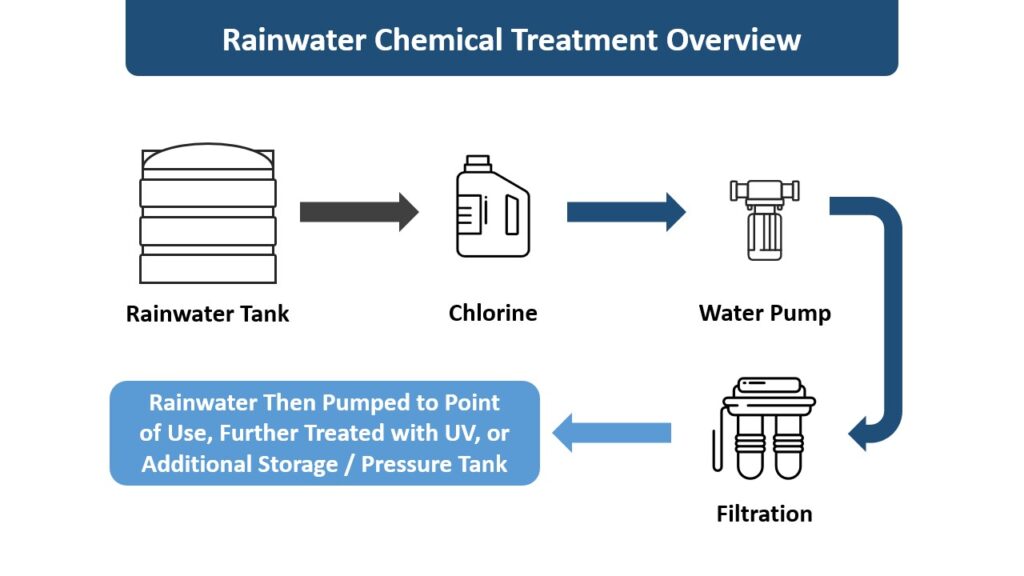

Chemical Treatment

Chemical treatment is an effective option to purify water collected from rainwater harvesting and provides several benefits exclusive to the practice. When performed correctly, chemical treatment is a good, nearly guaranteed option for purifying rainwater up to drinking quality water therefore making it safe for potable applications. In fact, chemical treatment is the method of water treatment often performed by municipalities that supply water to the majority of residents across the United States.

Common Chemical Used in Rainwater Treatment

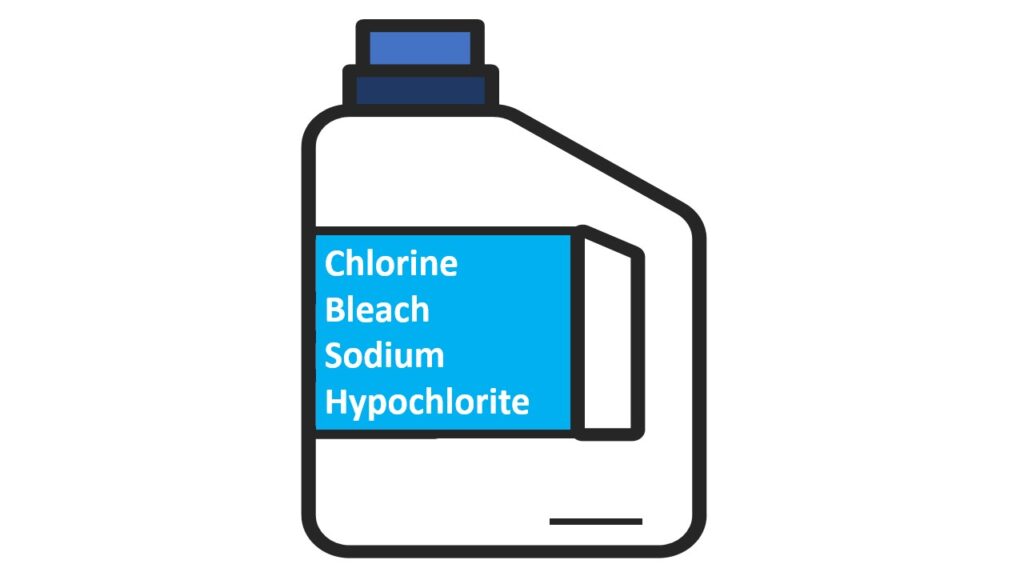

Chlorine is the chemical commonly used in water treatment to disinfect the harvested rainwater of pathogens that may be present. When chlorine is used to treat water, the process is known as chlorination. Chlorine is the active component and disinfecting agent that actually performs the action of purification by destroying and killing pathogens.

There are two main sources used to supply chlorine. The first is common bleach as used in laundry and cleaning and that can be readily purchased at many local stores. The second is liquid sodium hypochlorite, which often requires purchasing from a supplier or distributor and most often is easier to find online.

Recommendations on Using Bleach

Bleach, as it is commonly known, is actually an aqueous solution of sodium hypochlorite. Aqueous means of or containing water. It is the sodium hypochlorite that serves as a source of chlorine for active water treatment. Bleach often has a lower concentration (i.e., strength) of sodium hypochlorite compared to products listed simply as sodium hypochlorite, marking the difference between the two chlorine sources. The sodium hypochlorite concentration of many common household bleach products ranges from 4% to 8% sodium hypochlorite. The stronger the concentration of sodium hypochlorite, the more effective it will be in purification and the less volume of chemical that will be required.

A table is included further below of recommended bleach amounts based on the concentration strength of active sodium hypochlorite and the volume of water to be treated.

Many commercially available bleach products are not simply sodium hypochlorite and water but also contain additional ingredients and additives. Common examples include fragrances, dyes, soaps and surfactants. When shopping for a bleach product to use in the treatment of harvested rainwater, do not use a bleach labeled as splash-less, splash-free, or that has detergents, fragrance or added colorants. The best bleach product for rainwater treatment will be ANSI/NSF 60 certified; however, finding products with this label or the information readily available can be difficult.

Recommendations on Using Sodium Hypochlorite

Product solutions listed as sodium hypochlorite are often a stronger strength, more pure option for treating a rainwater supply. These products are typically available in strengths that range from 5% to 12.5% concentration. The greater concentration means the solution is more effective in purification and less volume will be needed. Stock solutions of sodium hypochlorite are ideal for larger rainwater collection tanks handling larger volumes of water. Sodium hypochlorite products are most often sold as a pure solution of water and sodium hypochlorite, meaning there is no concern of additives. Due to manufacturing standards and common use, it is easier to find an ANSI/NSF 60 certified sodium hypochlorite product compared to bleach.

Benefits of Using Chlorine for Rainwater Treatment

It was mentioned at the beginning of the Chemical Treatment section of this post that there are several benefits exclusive to the practice of treating rainwater with a chemical, in this case chlorine. The benefits to chlorine rainwater treatment are: (1) residual chlorine and (2) no pre-filtration required.

Residual chlorine is the most known, considered, and important, especially as filtration is often still performed for total water quality. The term residual chlorine simply means that there is remaining active chlorine present in the water supply still capable of performing disinfection if necessary. This concept extends the effectiveness of chemical treatment beyond the initial treatment, helping to maintain water quality and purity should the water become impacted by unclean water or a pathogen source. The U.S. EPA recommends a chlorine residual up to but no greater than 4 PPM (4 mg/mL) for effective, continuous treatment. The best way to achieve this is to purchase and set up a chlorine injection dosing system.

On the second benefit, as chlorine treatment is a chemical activity that dissolves and works throughout the water, filtration to remove sediment and reduce turbidity is not required. Chlorine based rainwater purification will work whether the water is cloudy, has debris in it, or otherwise. While this may not be relevant in most use cases, it is still an important point and means that treatment can occur directly in the rainwater container. If a cloudy water supply is to be treated, more chlorine may need to be added for proper disinfection.

Important Points on Using Chlorine for Rainwater Treatment

Using chlorine (bleach / sodium hypochlorite) for rainwater treatment is NOT considered effective against a parasite species known as Cryptosporidium and may not be wholly effective against Giardia. These pathogens are commonly found in animal feces and can therefore be common in rainwater that is collected from a roof with regular animal activity. To ensure Cryptosporidium and Giardia are removed whenever using chlorine, the options are to (1) use an ANSI/NSF 53 cartridge filter rated to remove Cryptosporidium-sized particles that are 5 microns or larger; or (2) use an ANSI/NSF 55 certified UV system capable of 40 mJ/cm2 dose strength.

Another important point: do not use pool treatment chlorine products, such as tablets, for purification of a rainwater supply. These products can oftentimes include a cyanide-based byproduct that can be hazardous to human health as pool water is not intended for consumption but for safety.

A final point on using chlorine from bleach or sodium hypochlorite. These products tend to have a definite shelf life. Over time, the sodium hypochlorite chemical in solution will degrade or break down and is no longer suitable as a source of free chlorine for disinfection. When purchasing sodium hypochlorite or bleach, do not buy more than you can use within the product’s estimated shelf life. When storing sodium hypochlorite or bleach, store in a cool, temperature-controlled environment away from direct sunlight and heat sources as these will diminish bleach shelf life.

How Much Bleach or Sodium Hypochlorite to Use

How much bleach or sodium hypochlorite to use for proper disinfection of a rainwater harvesting tank will depend on both the total volume of water to be treated and the concentration strength of the chemical solution. We have compiled a table of recommended bleach / sodium hypochlorite dose volumes based on various concentrations and common water volumes for rainwater tanks.

| Volume of Water | Amount of 4% Bleach | Amount of 6% Bleach | Amount of 8% Bleach | Amount of 10% Bleach | Amount of 12% Bleach |

|---|---|---|---|---|---|

| 50 Gallons | 22.5 mL | 18.75 mL | 15.5 mL | 12.9 mL | 10.75 mL |

| 100 Gallons | 45 mL | 37.5 mL | 31.25 mL | 25.8 mL | 21.5 mL |

| 250 Gallons | 112.5 mL | 93.75 mL | 78 mL | 64.5 mL | 53.75 mL |

| 500 Gallons | 225 mL | 187.5 mL | 156.25 mL | 129 mL | 107.5 mL |

| 1000 Gallons | 450 mL | 375 mL | 312.5 mL | 258 mL | 215 mL |

| 2000 Gallons | 900 mL | 750 mL | 625 mL | 516 mL | 430 mL |

| 5000 Gallons | 2250 mL | 1875 mL | 1562.5 mL | 1290 mL | 1075 mL |

| 10000 Gallons | 4500 mL | 3750 mL | 3125 mL | 2580 mL | 2150 mL |

While at first glance, the values in the table may seem to be large volumes of bleach / sodium hypochlorite. However, the opposite is actually true.

Consider the following conversion approximates: 1 US Tablespoon = 14.8 mL; 1 US Cup = 236.5 mL; 1 US Pint = 473.2 mL; 1 US Gallon = 3785 mL. Based on these conversions, treatment of 10,000 gallons of rainwater with a low 4% strength bleach would only require a bleach dose around 1.2 gallons.

Potential Downsides to Chlorination

A potential downside to chlorination is the requirement for repeat application, the necessity for onsite stock solutions, measuring the volume of chlorine to add, and potentially testing the water for adequate chlorine levels. These are some reasons why UV light systems are the preferred option for rainwater treatment.

How Often to Perform Chlorination

Chlorination in rainwater harvesting will need to be performed as more rainwater is collected and added to the collection container to replace water that was used. Residual chlorine will only be effective in treating new rainwater to a point. How often to perform chlorination is highly variable and application specific based on when chlorination was last performed, total current volume, water use rates, rainfall frequency and amounts. For these reasons, using a home chlorine test to measure active chlorine levels is recommended as they can be used as a reference point in whether more chlorine is needed and how much.

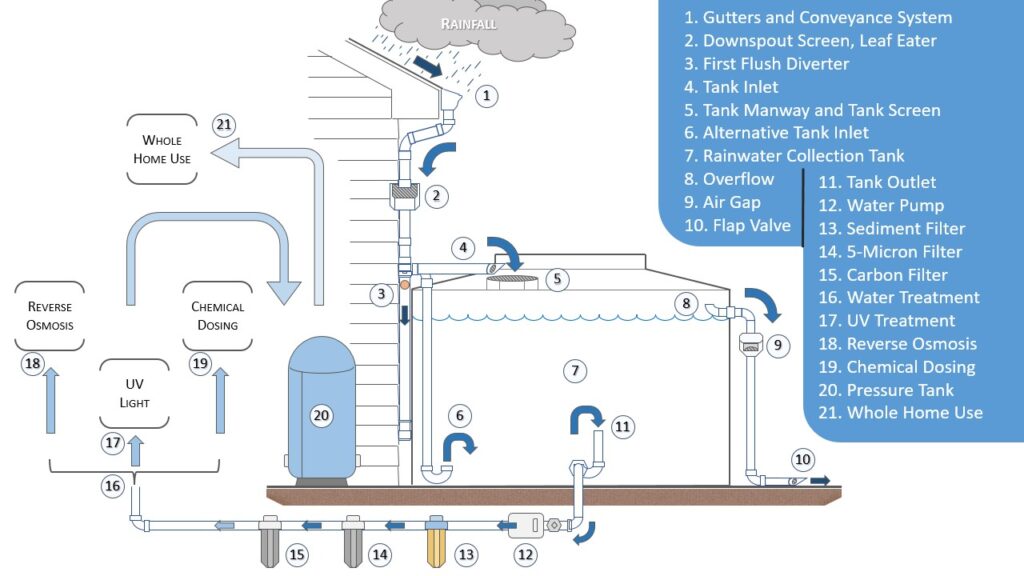

Overview of a Potable Rainwater Harvesting System

The following is an infographic that provides an overview of a potable rainwater harvesting system. For more details on the following infographic and a comprehensive overview of potable rainwater harvesting systems, see our Rain Tanks Series | Rainwater Harvesting for Potable Water.

Takeaway | Rainwater to Drinking Water

There are two main methods recommended to turn harvested rainwater into drinkable water that is safe for potable applications. Ultraviolet light treatment is a preferred treatment method that is effective and easy to set up and maintain for personal use scenarios. Chlorine based chemical treatment can be a bit more intensive and requires more hands-on involvement to maintain consistent disinfection and rainwater purity. The right method will depend on your personal setup and goals.

If you have further questions on implementing your own rainwater harvesting system, consider reviewing our additional Rain Tanks Series posts, our you can contact our professional support staff and we can direct you to recommended equipment based on our available product selection.