IBC containment tanks are secondary containment and spill prevention products engineered to control materials spilled from intermediate bulk containers whenever an accident occurs. Material release is an unintended but common problem that can occur during normal use operations.

Examples of accidents that can lead to a release include forklift puncture, equipment impact, and drops during handling. Other examples include incomplete connections, incorrect pumping procedures, unchecked valves, failing seals or gaskets, and container degradation from long term chemical wear and tear.

An IBC is an intermediate bulk handling container capable of spilling a fairly substantial volume of liquid in the event of an accident, and secondary containment is used as a safety precaution to contain any material that is released during such scenarios.

Containment products are designed to improve application security by providing a designated filling, dispensing and storage location for liquid holding containers while onsite and in use. Common types of containment include specialized pallets, open top spill berms or basins, concrete dikes, and double walled IBC totes that feature built in containment.

Secondary containment measures are many times required by law regulations. The regulations are designed to keep spilled, hazardous materials away from workers, nearby equipment and containers, as well as prevent environmental release such as through storm drains where they could go on to affect the environment downstream.

Regulatory Containment Codes for IBCs

In the U.S., there are various regulatory laws concerned with the correct usage and housing of hazardous materials and chemical storage containers, which includes IBC totes. Secondary containment is often necessary to meet and/or exceed these rule requirements as well as to pass company inspections and avoid penalty fines.

A common rule for containment is that a designated device or location must be made of resistant material with a volume that is equal to 10% the total container volume or equal to the largest container, whichever is greater between the two.

Regular codes that apply to IBC use and containment practices include:

- RCRA: Resource Conservation and Recovery Act ‒ and Title 40 Code of Federal Regulations (CFR) Part 264 requirements for best practice management of resources and sensitive materials.

- SPCC: Spill Prevention Control and Countermeasure ‒ standards listed by the U.S. Environmental Protection Agency (EPA) in handling material / chemical releases.

- NPDES: National Pollutant Discharge Elimination System ‒ as related to Title 40 CFR 122 and the Congressional Clean Water Act Section 402.

- OSHA: Occupational Safety and Health Association Standard 1910 ‒ requirements pertaining to the handling, containment and worker security of defined hazardous materials.

- UFC / IFC: Uniform / International Fire Codes ‒ that involve the handling, dispensing and transfer of flammable or combustible commodities.

To summarize, containment is necessary for an IBC application when required to comply with EPA Title 40 CFR 264, 40 CFR 122, SPCC, NPDES, OSHA, and/or UFC and IFC standards, codes, and requirements.

Common Applications with IBC Containment Needs

Many industries and IBC use-scenarios require secondary containment measures and protocols or can benefit from them. The most frequent job applications requiring material containment include the chemical process industry (CPI), modern product manufacturing plants, handling process intermediates, solvent and production chemicals, oil and metal refineries, the energy production sector, waste and wastewater treatment, waste oil containerization, and general product waste accumulation and handling.

Hazardous Chemicals that Often Need Containment by Regulation:

- Hydrochloric Acid – Muriatic Acid, HCl

- Hydrofluoric Acid – Hydrogen Fluoride, HF, Fluorane

- Sulfuric Acid – Vitriol, H2SO4, Sulphuric Acid

- Phosphoric Acid – Orthophosphoric Acid, H3PO4, Phosphoric (V) Acid

- Acetic Acid – Ethanoic Acid, C2H4O2

- Sodium Hypochlorite – Bleach, NaOCl

- Sodium Hydroxide – Caustic Soda, NaOH, Lye

- Hydrogen Peroxide – H2O2

- Nitrogen Oxides – NO, NO2, N2O4, N2O3

- Formaldehyde – Methanal, CH2O

- General Hydrocarbons / Petroleum Distillates – Ethylene, Propylene, CnHn

Our Specialized IBC Containment Products | Overview

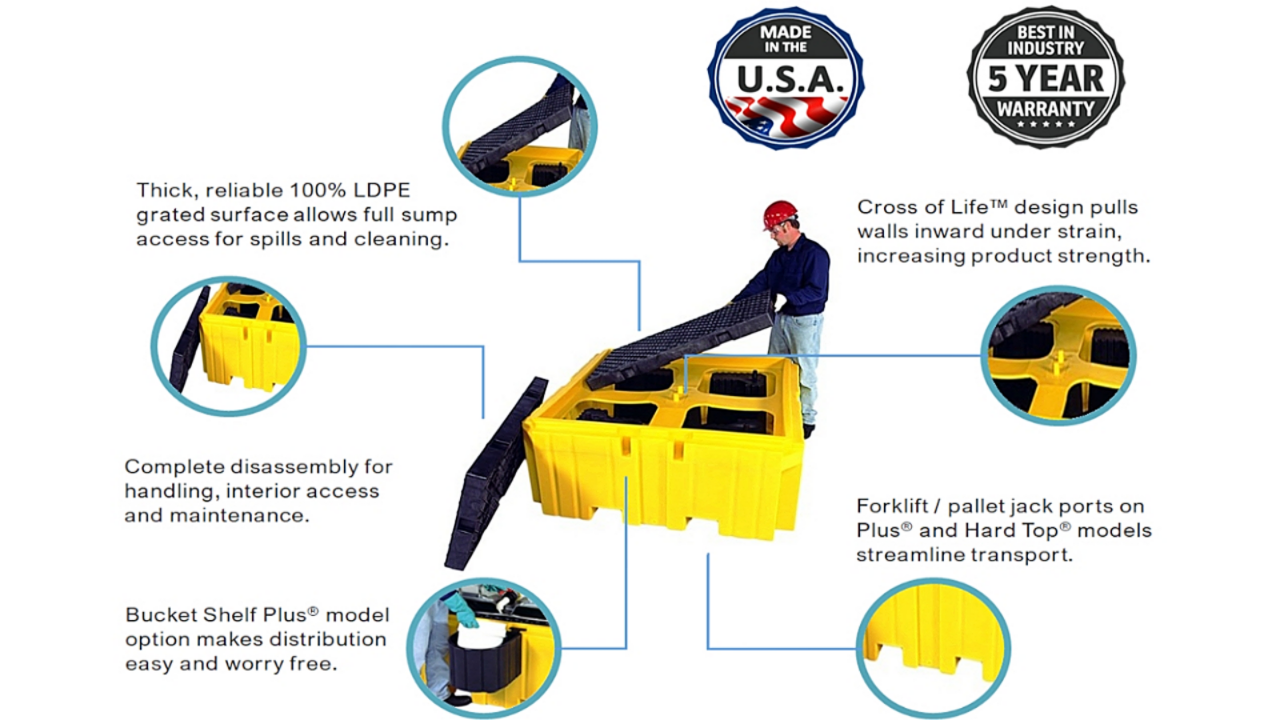

Our specialized IBC containment includes UltraTech™ brand secondary containment products as an all-in-one solution to meet the codes in place for handling scenarios and events involving spills, leaks, or so-called “catastrophic” accidents. The IBC Spill Pallet®, the Spill Pallet Plus®, and the Hard Top Pallet® are our top engineered, top recommended containment solutions specialized for CFR, SPCC, and NPDES compliance. They have been designed, made, and tested for top-to-bottom compatibility with many of the applications and hazardous materials, chemicals, and liquids commonly used within today’s industries.

Description: Product features a removable grated holding deck surface with a designated underbody containment sump used to capture leaks, spills, drips or large releases that may occur during the use of Intermediate Bulk Containers (IBC’s).

Construction: Products are 100% constructed from industrial grade virgin quality Linear Low Density Polyethylene (LLDPE) that provides them with:

- Superior chemical reliability

- Physical impact durability

- Greater structural rigidity

- Rust and corrosion protection

- Limited weathering concerns

- Low total weight

Technology: Proprietary “Cross of Life” design imparts greater product resistance to weight load stress and wall sag problems commonly associated with inferior containment products. This allows for handling heavier containers and the highest specific gravity fluids.

Engineering: Five (5) internal all polyethylene support columns evenly distribute IBC product weight load. Engineered for end-user operations, they are removable, cleanable, and manufactured from rigid, resistant LLDPE.

Movement: Several product options include forklift channels built into the base of the containment sump that can be used to allow easy maneuverability, handling, and storage of IBC containment basins.

Outdoor Use: In general, outdoor use is restricted due to potential weather accumulation in the sump that can affect total containment capacity. For outdoor use, place pallets under shelter, add a pullover cover, or choose the Hard Top Spill Pallet® product model. All containment basins feature a UV protective additive for lasting security against sun exposure and fluorescent lighting.

Temperature: The products are approved and rated for ambient temperature conditions ranging between -40°F to 160°F.

Drain Options: A 3/4 inch polypropylene bulkhead sump drain can be added to all product basins prior to purchase for a minor cost or can be easily self-installed on receipt. The Spill Pallet Plus® model Spill Bucket can also be fitted with a bulkhead drain that allows accidental overflow conditions to spill over into the sump for containment and cleanup.

IBC Containment Product Engineering Details

Uniformly Distributed Load Info

The available spill containment products are rated and approved for specific weight capacities from 8,500 lbs up to 16,000 lbs. These load ratings are approved only for uniformly distributed loads (UDLs).

A UDL refers to an equal displacement of an object’s weight along its bottom interface with the object it is placed on. In other words, the downward force the top object exerts on its bottom support must be equal, i.e., uniform, throughout the base of the supported object, in this case an IBC container.

Composite IBCs and most all-poly IBCs have an entirely flat base footprint that gives them equal displacement and therefore provide a uniformly distributed load. Metal IBCs, Excalibur IBCs, and a few other models have four (4) individual legs or feet that focus the container’s weight and do not produce a uniformly distributed load.

IBC totes that feature legs rather than a flat base should not be used with a spill pallet product without additional support. To use legged IBCs, place a 12” x 12” slab of steel with a 1/8″ to 3/16” thickness on the grate surface under each leg of the IBC. This creates a flat bottom support that displaces the weight and provides a uniformly distributed load.

Poly Compatibility

LLDPE is a modern synthetic material that provides significant resistance and tolerance against many frequently used chemicals. Even if the material does express some sensitivity, the length of exposure with the containment sump for spilled liquids is much shorter than in storage container scenarios. Due to this, the basin is acceptable for some harsh, corrosive chemicals that would be otherwise incompatible with LLDPE long term.

Secondary containment is only intended to store released materials for short durations: ideally a couple hours to 24 hours up to 7 days at the most. Inspections should occur regularly, if not daily, to check for releases and be cleaned as promptly as possible. Doing so will ensure compatibility, product service life, and reduce risks to workers and the environment.

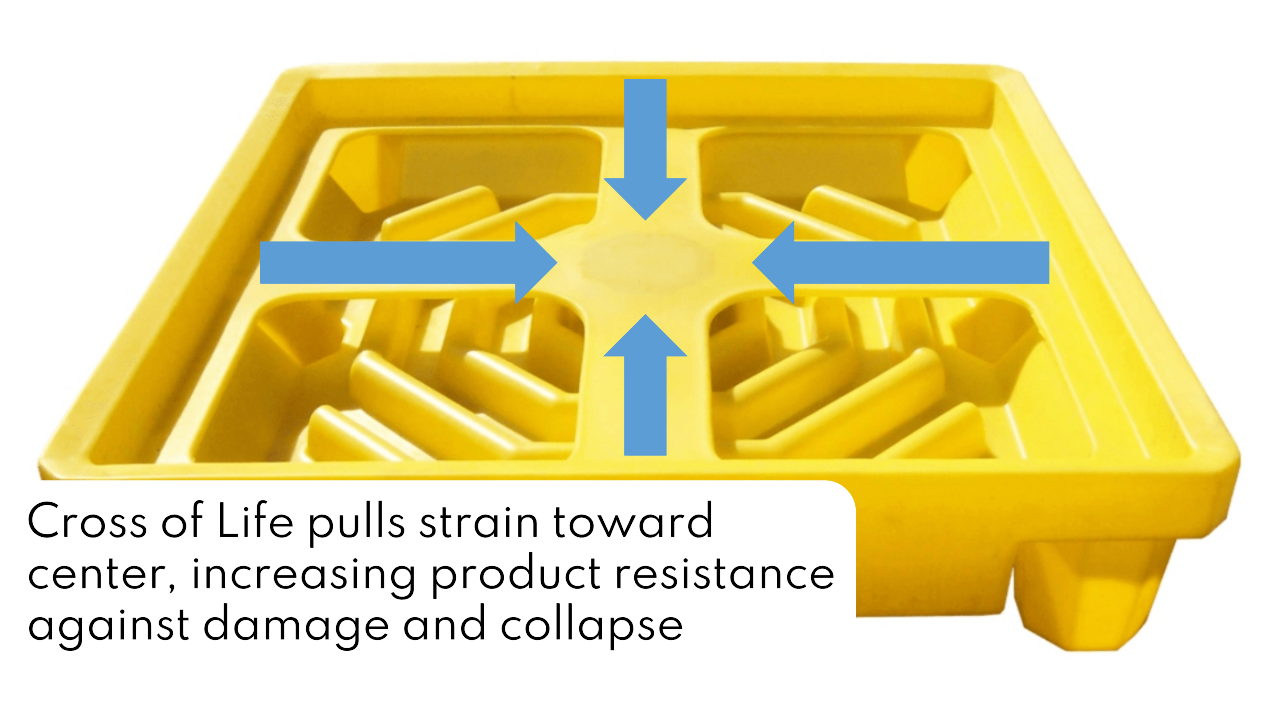

Cross of Life

Our recommended IBC secondary containment products are manufactured with a design unique among containment pallets. Given the name “Cross of Life”, this exclusive UltraTech® engineering connects all four sides of the containment unit and joins them at the center.

The design causes weight strain to pull inward rather than push outward and as a result increases the unit’s total strength resistance. This is an improvement over other IBC containment products that distribute their weight outward to the sidewalls and can experience wall collapse over months of polyethylene creep stress due to load bearing.

Our IBC Containment Products

UltraTech IBC Spill Pallet®

Simple engineering, effective results. The IBC Spill Pallet® model is our featured containment solution that offers the greatest load capacity and sump containment volume of all available products. This model has a verified weight tolerance up to 16,000 lbs for uniformly distributed loads (UDL). The sump has a containment volume up to 400 gallons, making it suitable for increased applications. The IBC Spill Pallet® is rated for stacking totes two high up to 400 gallons each for 800 gallons total while maintaining regulation compliance.

Product Features:

- Max Load Capacity: 16,000 Pounds

- Containment Volume: 400 Gallons (1,514 Liters)

- Two (2) IBCs Stackable on Single Pallet

- Sump Dimensions: 58¾” W x 58¾” L x 33” H

- Product Weight: 444 Pounds

- 52” x 52” Grated Load Surface with Minimized Void Space

- Accepts IBC Containers up to 50” Inches Wide

- 100% LDPE Construction

- Removable, Cleanable Top Grate and Support Pylons

- UV Stabilized Resin for Extended Service Life

- Top Platform Offers Easy Forklift Access

- Does Not Feature Forklift Transport Channels

- 5 Year Manufacturer Warranty on Material / Workmanship Defects

UltraTech IBC Spill Pallet Plus®

Cost effective, intuitive and versatile. The IBC Spill Pallet Plus® model is our most popular and lowest priced containment solution. Suitable for containment of IBCs up to 330 gallons. When compared to the basic Spill Pallet®, the Plus® model has a lower weight load of 8,500 lbs UDL and sump capacity of 365 gallons but offers increased versatility and maneuverability.

The Plus® model includes two-sided forklift channels (front and back) for improved handling and mobility. The product has a reduced total height that provides an overall low profile and easier access for use. An optional 3 gallon Bucket Shelf attachment is available that accommodates 5 gallon buckets for containing spills during distribution.

Product Features:

- Max Load Capacity: 8,500 Pounds

- Containment Volume: 365 Gallons (1,382 Liters)

- Suitable for One (1) IBC per Pallet

- Sump Dimensions: 62” W x 62” L x 28” H

- Product Weight: 324 Pounds

- 52” x 52” Grated Load Surface with Minimized Void Space

- Reduced, Low Profile Design Only 28” Inches Tall

- Accepts IBC Containers up to 50” Inches Wide

- 100% LDPE Construction

- Removable, Cleanable Top Grate and Support Pylons

- 3 Gallon Bucket Shelf Option with Option for Drain to Sump

- Outdoor Pull Over Cover Option for NPDES Compliance

- UV Stabilized Resin for Extended Service Life

- Top Platform Offers Easy Forklift Access

- Integrated Forklift Channels Simplify Movement and Handling

- 5 Year Manufacturer Warranty on Material / Workmanship Defects

UltraTech IBC Hard Top Spill Pallet®

Superior IBC product containment, complete outdoor stormwater approval. The IBC Hard Top Spill Pallet® model offers security against weather elements while still providing easy entry for use. Maximum load capacity of 8,500 lbs and 365 gallon sump volume exceeds performance standards for IBCs up to 330 gallons.

The full outer hard top shell protects both sump and IBC from rain or snow accumulation, mixing and stormwater runoff. Roll away top and swing doors shield internal IBC containers from direct sun effects and damage. Products can be locked to limit worker entry or prevent unwanted access to sensitive materials. The Hard Top Spill Pallet® offers the same low platform height and fork-liftable design as the Plus® model without the Spill Bucket option.

Product Features:

- Max Load Capacity: 8,500 Pounds

- Containment Volume: 365 Gallons (1,382 Liters)

- Suitable for One (1) IBC per Pallet

- Sump Dimensions: 64½” W x 62” L x 28” H

- Full Product Dimensions: 64½” W x 62” L x 96” H

- Internal IBC Load Space: 52” W x 52” L x 61 ”H

- Product Weight: 525 Pounds

- 100% LDPE Construction

- Lockable Design Increases Outdoor Security

- Meets NPDES Phase II No Exposure Conditions

- Removable, Cleanable Top Grate and Support Pylons

- UV Stabilized Resin for Extended Service Life

- Top Platform Offers Easy Forklift Access

- Integrated Forklift Channels Simplify Movement and Handling

- 5 Year Manufacturer Warranty on Material / Workmanship Defects

Video Details | About the Manufacturer

For more information and details about UltraTech, the manufacturer of these IBC secondary containment products, consider these video posts from the company.

About UltraTech

UltraTech’s Manufacturing Facility

Takeaway | IBC Secondary Containment

Secondary containment is often a necessary safety protocol when hazardous materials, chemicals or sensitive commodities are involved. Secondary containment products such as the UltraTech IBC Spill Pallet are company assets used to implement these safety measures to protect workers, equipment and the environment, and meet codes and regulations for compliance.

National Tank Outlet is an industry leader and authority on polyethylene products, storage tanks, and intermediate bulk containers. Visit our store page here. Our UltraTech IBC containment products can help your company meet CFR, SPCC as well as NPDES requirements and gain security with a simple and secure solution. If you have any questions, specific detail requests, or quote inquiries, contact us.

Spill Containment Solutions