Monitoring liquid levels in tanks is a common task in a wide range of industries and applications. From managing water resources in agriculture to handling caustic chemicals in industrial facilities, accurate tank level measurement ensures safety, efficiency in workflows, and optimal use of resources. The technology behind measuring onsite tank volumes has grown significantly with various product solutions engineered for different needs, storage cargo, and work conditions.

This post will explore non-contact tank level sensors, a modern and innovative approach to monitoring liquid levels. Non-contact sensors stand out for their ability to measure tank levels without having to be in direct contact with the liquid, making them ideal for challenging cargo, harsh environments, and sensitive substances. We’ll break down how these sensors work, the benefits they provide, and the options available from the National Tank Outlet that are capable of meeting your specific requirements. Whether you’re looking to upgrade your current tank setup or explore modern solutions, this guide will equip you with the knowledge you need.

What Are Non-Contact Tank Level Sensors?

Non-contact tank level sensors are innovative devices designed to measure the current liquid level inside a tank without coming into contact with the liquid itself.

Unlike traditional sensors or measurement tools, which require physical interaction and placement within the substance to provide readings, non-contact sensors operate remotely by using technologies such as ultrasonic waves, radar signals, or optical measurements. This new approach allows the sensors to gather highly accurate data while maintaining complete separation from the liquid being monitored.

The main distinction between contact and non-contact sensors lies in their operating mechanism. Contact sensors rely on placed probes or submersible components that interact physically with the liquid, while non-contact systems transmit signals from a distance, bouncing waves off the liquid’s surface to calculate stock levels. This advancement eliminates many of the limitations of contact-based tools, offering greater flexibility and reliability.

Why They’re Important

Non-contact sensors have been engineered and built for situations where direct contact with the liquid is impractical, hazardous, or imprecise. Industries dealing with harsh chemicals, volatile solutions, fragile mixtures, high purity materials, or food grade products can rely on non-contact tech to maintain high safety standards and prevent contamination. For example:

- Safety: Certain chemicals or high temperature liquids can damage sensors on contact or extended exposure and put maintenance personnel at risk when they need cleaned or replaced. Non-contact sensors remove these issues by keeping all working parts out of the liquid or even, as in the case of radar sensors, fully outside the tank.

- Chemical Compatibility: Some liquids can corrode or degrade traditional contact sensors. Non-contact systems avoid this problem altogether by eliminating exposure to the liquid.

- Preventing Contamination: When handling sensitive cargo like food, beverages, or pharmaceuticals, even minimal contact with external devices can result in contamination and be unacceptable for industry standards. Non-contact sensors provide a safe and clean alternative for these critical applications.

Non-contact tank level sensors have reshaped liquid measurement in storage containers, offering a professional product solution for environments that demand precision along with safety and cleanliness.

Work Conditions Suitable for Non-Contact Sensors

Non-contact tank level sensors have been engineered to excel in a variety of extreme environmental conditions. Their construction material and design functionality make them valuable for industries with demanding operations and work conditions.

- High Temperatures: Non-contact sensors like radar are specifically designed to work reliably in tanks handling elevated temperatures. This makes them suitable for applications such as thermal fluid storage, industrial chemical processes that involve heat, and business activities that require heated materials.

- High Pressures: Ultrasonic sensors can perform consistently in pressurized tanks, where traditional sensors might fail or other tools be unsuitable.

- Corrosive Environments: Materials used in the construction of radar and ultrasonic sensors, such as durable polymers or corrosion-resistant metals, allow these systems to withstand exposure to caustic chemicals or reactive substances should they be exposed due to fully filled containers or vapors. This is particularly beneficial in chemical storage or wastewater treatment.

- Foam or Vapor: Many sensing technologies struggle with interference from foam, vapor, or steam. Radar and ultrasonic sensors can effectively penetrate these obstructions to deliver accurate measurements reliably in dynamic tank environments.

- Outdoor and Remote Applications: Non-contact sensors are heavy duty, professionally built to handle outdoor setups where exposure to environmental elements like rain, dust, or extreme weather might wear down other systems. Their robust design ensures long term performance in industries such as agriculture, construction, and marine operations.

By effectively handling these work challenges, non-contact sensors provide versatility and durability while ensuring optimal tank monitoring across different demanding settings. Their resilience makes them an excellent choice for industries that require liquid level monitoring under hard working conditions.

How Do Non-Contact Tank Level Sensors Work?

Non-contact tank level sensors utilize advanced technologies to measure liquid levels without physical interaction. Here’s how the main types of non-contact sensors work:

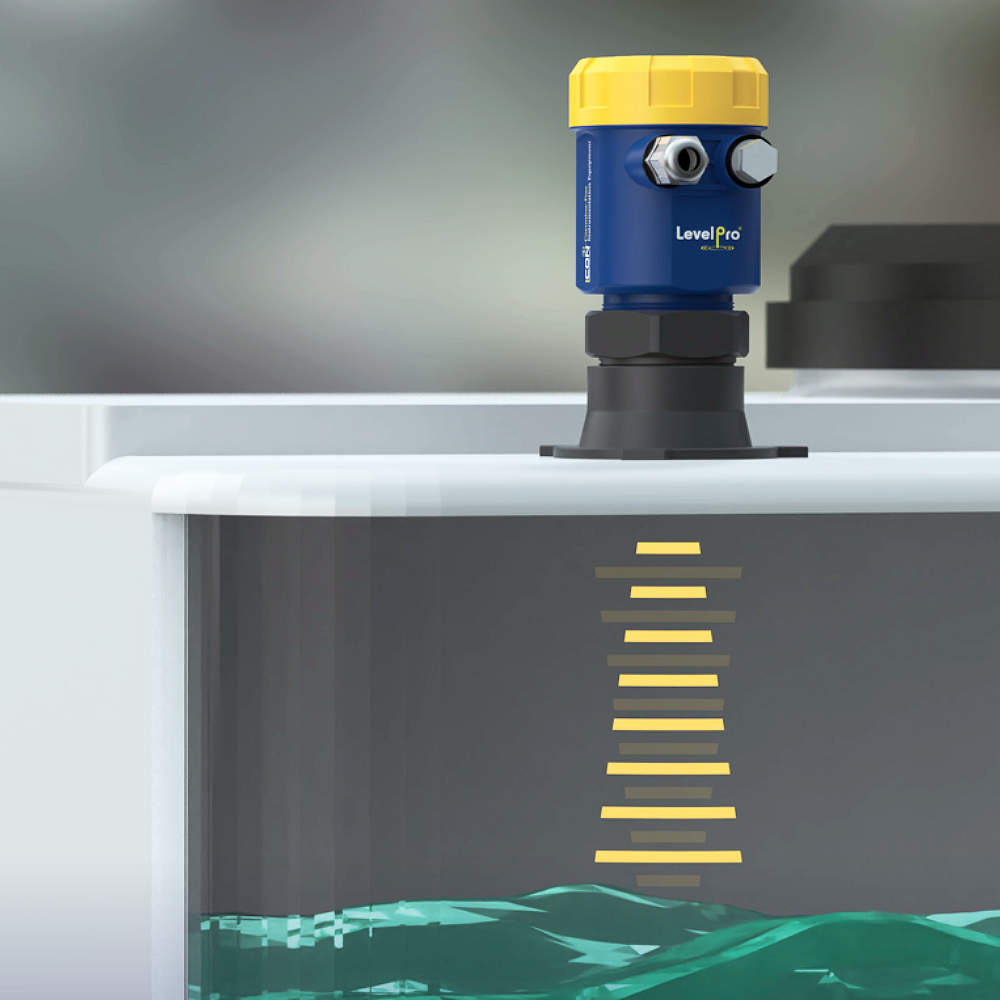

- Ultrasonic Sensors: These sensors emit high frequency sound waves toward the liquid surface. The waves bounce back, and the sensor calculates the distance based on the time it takes for the echo to return, thereby determining how much liquid is in the tank. This method is highly effective for applications requiring accurate, real time measurements.

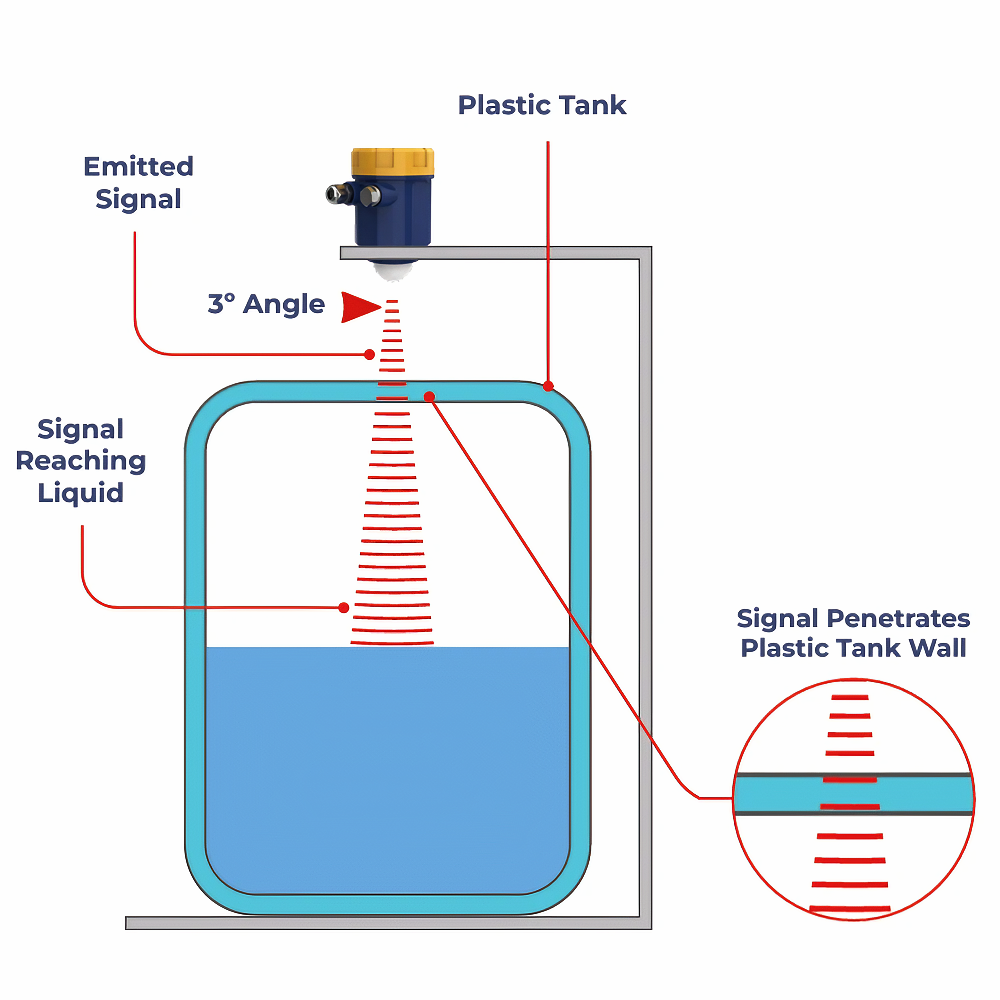

- Radar Sensors: Radar devices use electromagnetic waves to determine the distance to the liquid’s surface. The waves can penetrate potential obstacles like steam, dust, or foam, and when properly installed, can even perform measurements from outside the tank.

- Laser Sensors: These rely on laser beams to measure the liquid level. Similar to ultrasonic sensors, these products calculate the time for the beam to reflect back from the surface, providing an extremely precise measurement, often within millimeters. Laser sensors are ideal for tasks that require exceptional accuracy or involve clear liquids in deep tanks. Note, NTO Tank does not offer laser sensors at this time.

Each of these technologies operates on a simple yet effective concept: by determining the distance between the sensor and the liquid surface.

Functional Advantages

The non-contact approach provides several significant advantages that make these sensors a smart investment:

- Exceptional Precision: Non-contact sensors deliver reliable and accurate readings, even in environments prone to variables like temperature changes or liquid turbulence.

- Improved Safety: Because these sensors don’t interact directly with the liquid, they are ideal for hazardous applications as operators and sensors alike stay protected from exposure.

- Minimal Maintenance: With no direct contact with liquids, the risk of buildup, corrosion, or part wear is drastically reduced, resulting in lower maintenance costs and less frequent downtime.

Non-contact tank level sensors are a showcase to how technology and products continue to improve. Their ability to adapt to various environments while maintaining accuracy makes them a preferred choice across industries.

Interested in discovering the right sensor for your needs? Explore our selection of non-contact sensors and learn more about what they can do for your operations.

Types of Non-Contact Tank Level Sensors

Ultrasonic Sensors

Ultrasonic sensors operate by emitting high frequency sound waves that travel through the air until they reach the liquid surface. Once the sound waves hit the surface, they reflect back to the sensor. By calculating the time it takes for the waves to return, these sensors can precisely determine the liquid level within the tank.

Ultrasonic sensors are popular for their simplicity, reliability, and cost effectiveness. They excel in environments requiring real time, accurate measurements under relatively stable conditions.

Key Product Example:

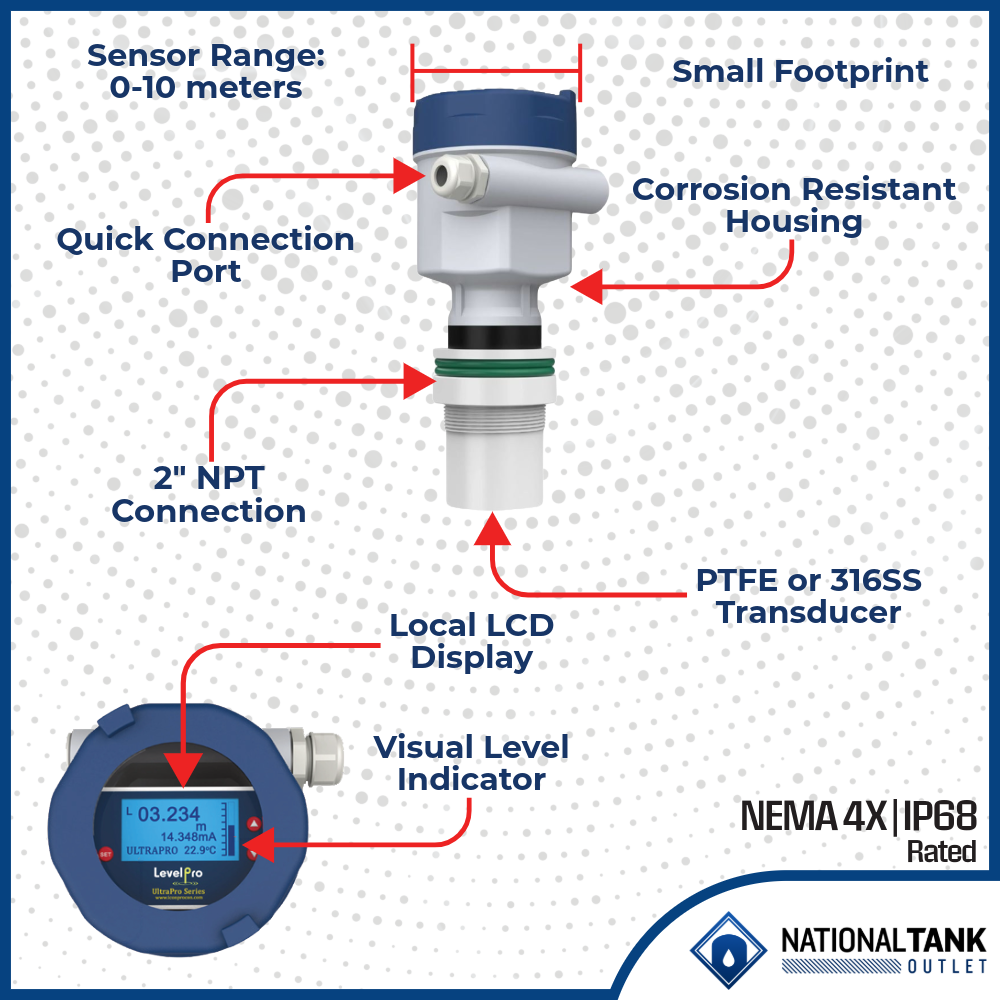

UltraPro 2000 Ultrasonic Electronic Level Sensor: This advanced sensor offers non-contact liquid level measurements with outstanding performance up to 0.15% accuracy. Its durable design and wide sensing range make it ideal for water tanks, chemical containers, and general purpose monitoring.

Additionally, its integrated LED display simplifies real time monitoring and visualization, even in harsh industrial settings.

Typical uses for ultrasonic sensors include water storage, agricultural systems, and chemical storage applications. With minimal maintenance requirements and straightforward installation, they are a reliable choice for many businesses, their employees, and their applications.

Radar Sensors

Radar sensors use electromagnetic waves to analyze liquid levels. This makes them exceptionally versatile. These sensors transmit radio waves that bounce off the liquid’s surface, similar to ultrasonic sensors, but the technology is better suited for handling variables such as foam, steam, and dust. Radar technology is particularly ideal for challenging environments and scenarios demanding high levels of precision.

The way radar sensors work allows them to be installed outside a tank and take measurements through the top of a plastic tank. Radar sensors thrive in demanding work conditions, including storage tanks under pressure, vacuum, or high temperatures, as well as environments with vapor or other obstructions that can interfere with other sensing technologies.

Key Product Example:

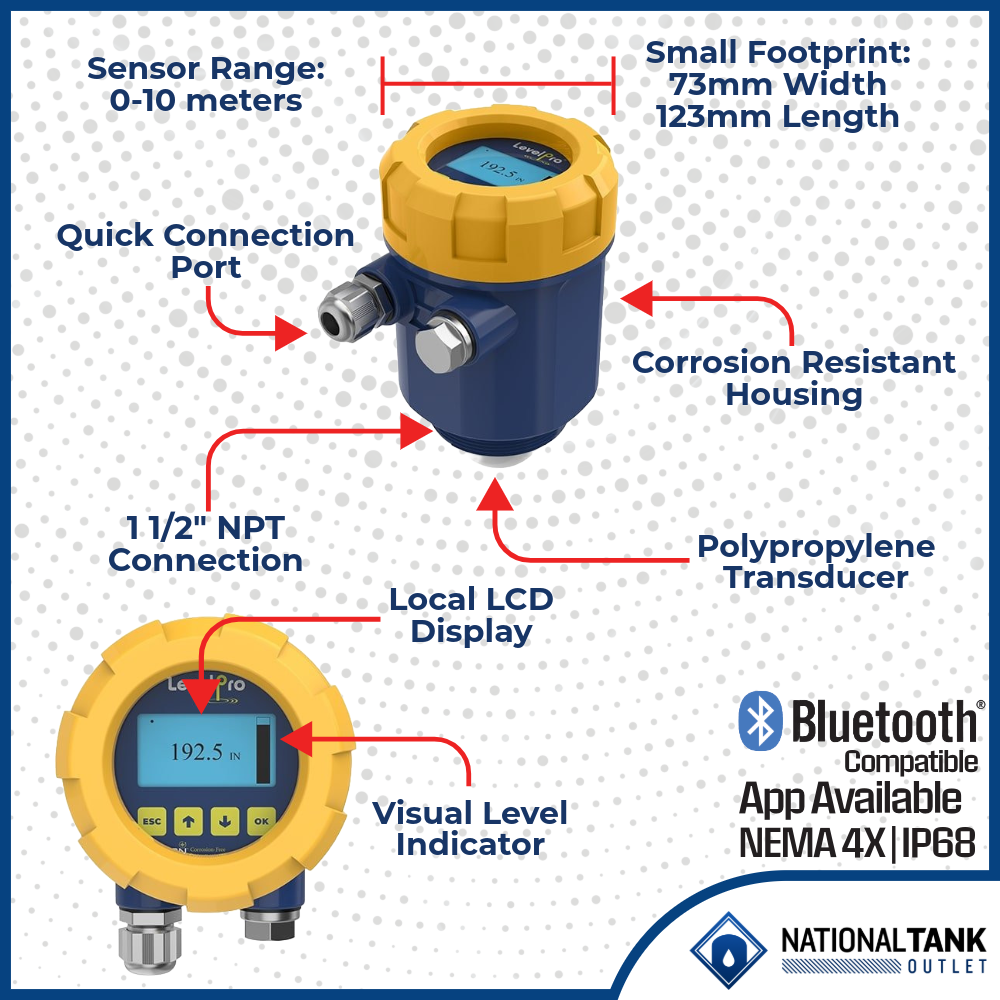

Levelpro Polypropylene ProScan 3 Radar Level Transmitter: Equipped with high performance 80GHz radar technology, this sensor delivers accurate, reliable readings up to ±2mm, even in extreme environments. The sensor’s SimplConnect™ design allows for seamless integration with external displays like the ShoPro Display.

These sensors have Bluetooth™ connection capability that offers modern flexibility for remote monitoring by a smart device and its free app. The ProScan 3 is durable, IP68-rated weatherproof, and resistant to aggressive chemicals, making it ideal for numerous applications.

Radar sensors are frequently employed in industrial sectors such as chemical processing, petroleum storage, and in food grade tanks. With their non-contact measurements and ability to measure from a tank’s exterior to dynamic performance, radar sensors are a premium, professional choice for almost any storage tank application.

Common Tank Types That Use Non-Contact Sensors

Non-contact tank level sensors are versatile, designed to work with a variety of tank types across industries and businesses. Here are some common tank types that benefit from and use these sensors:

- Day Tanks: Precise monitoring of small to large day tanks with high fill-dispense frequencies often found in industrial or commercial setups.

- Batch Tanks: Measuring liquid levels in batch tanks used to process specific ingredients and quantities, such as mixing or preparation in manufacturing or chemical applications.

- Chemical Storage Tanks: Reliable monitoring of corrosive or hazardous chemical storage tanks and ensuring safety and accuracy with minimal to no risk.

- High Purity Tanks: Environments like pharmaceuticals, research and development, laboratories, or food production where maintaining pristine conditions is critical.

- Wastewater and Neutralization Tanks: Tracking levels in facilities requiring wastewater treatment or neutralization tanks while avoiding interaction with potentially hazardous or reactive cargo.

- Bulk Storage Tanks: Reliable readings of high capacity bulk storage tanks in agricultural, fuel, or water management applications.

- Plastic and FRP Tanks: Sensors, especially radar technology, are well suited for non-metallic tanks as the material does not cause interference.

- Metal Tanks: Ultrasonic sensors feature a 2” NPT style connection for placement in bungs or bulkhead fittings for direct reading inside the tank, making them suitable for metal storage tanks.

- Tanker Trucks: Non-contact sensors can be utilized in mobile applications, offering convenient level monitoring for liquids in transit.

Benefits of Non-Contact Tank Level Sensors

Non-contact tank level sensors provide several significant benefits when compared to traditional contact-based systems, making them a preferred choice for modern monitoring needs:

- Reliability and Longevity: By avoiding direct interaction with the liquid surface, non-contact sensors minimize wear and tear and are less prone to damage or malfunctions caused by the medium being measured, contributing to an extended operational lifespan.

- Usable in Harsh Conditions: These sensors excel in environments where traditional systems would struggle. For many use cases, non-contact sensors maintain their functionality and integrity.

- Reduced Risk of Corrosion and Contamination: Corrosion can degrade sensors over time, particularly in tanks with caustic or reactive liquids. Non-contact sensors eliminate that risk, likewise creating a contamination-free environment.

Take the next step and shop the non-contact sensor options available from NTO Tank to upgrade your setup.

Non-Contact Tank Level Sensors Available from the National Tank Outlet

At NTO Tank, you’ll find a versatile selection of non-contact tank level sensors designed to meet most industry needs. These sensors incorporate today’s tech to deliver reliable performance while prioritizing ease of use. Some standout features of the products include:

- Ease of Installation: NTO Tank’s sensors are designed for straightforward installation with NPT threads or mounting brackets to mount on a wall outside the tank, often requiring minimal tools and setup time. Whether you’re upgrading an existing system or implementing a new one, they ensure a hassle free setup.

- Compatible with Various Tank Types: The sensors support a wide range of tank materials and configurations, including vertical, horizontal, above ground, and underground tanks. This flexibility makes them ideal for many operations and multiple tank systems.

- User Friendly Designs: From clear displays and detailed interfaces to smart alert systems, NTO’s non-contact sensors have been engineered for straightforward, easy use. Their simple controls and accessible features, (Bluetooth™, smart apps) allow operators to monitor liquid levels with confidence, regardless of technical expertise.

Applications Across Industries

Non-contact tank level sensors from the National Tank Outlet are built to suit various applications with versatility and reliability. Common industries using our tank monitors include:

- Agriculture: From irrigation systems to fertilizer storage, tank sensors ensure efficient water and resource management, helping farmers maintain optimal levels without overuse, waste, or shortages.

- Wastewater Management: Precision monitoring ensures the safe handling of liquids in tanks containing harsh chemicals or contaminants. These sensors are used to monitor fluctuating tank levels, prevent spills, and maintain compliance with industry standards.

- Chemical Storage: With the ability to function in extreme environments, these tank sensors provide safe, accurate monitoring of caustic, corrosive, hazardous, or volatile chemicals.

- Food and Beverage: For industries with high cleanliness standards, non-contact sensors avoid direct liquid contact to ensure hygienic containment in applications like beverage production, dairy systems, and syrup storage.

- Mining and Mineral Processing: The sensors deliver reliable performance for monitoring slurry levels, chemical reagents, and water in mining and mineral processing. Their durability delivers long term performance in abrasive and corrosive environments common to this industry.

- Marine and Shipping: These sensors can be used to monitor ballast water, fuel, and other tank levels aboard ships and maritime vessels. Their non-contact design is ideal for environments where accessibility is limited or difficult, which enhances both safety and convenience.

- Pharmaceutical: Designed for high purity environments, non-contact sensors ensure clean monitoring of liquids used in drug manufacturing, R&D, or storage. Their precision measurement supports this industry’s high quality control requirements.

- Power Generation: Non-contact tank sensors can be used for monitoring fuel, cooling water, or chemical tanks in power plants and onsite power generation.

By meeting the specific challenges of diverse industrial and environmental needs, NTO Tank’s non-contact sensors stand out as indispensable tools for efficient liquid management.

By incorporating the National Tank Outlet’s non-contact tank level sensors into your operation, you can achieve reliable performance and long lasting monitoring. Explore our product range today to find the ideal solution for your tank monitoring needs.

Choosing the Right Non-Contact Sensor for Your Needs

Select the ideal non-contact tank level sensor to ensure accurate performance and efficiency. Here are some key consideration points when making your decision:

Consideration Points

- Tank Size and Configuration: The dimensions and shape of your tank can impact sensor performance, especially for technologies like ultrasonic and radar. Consider sensors with the correct range and coverage for your specific tank setup. Small tanks may require sensors with tighter calibration, while large tanks may benefit from options with extended range.

- Tank Material: The make of your tank — whether it’s metal, plastic, or another material — can interact with certain sensing technologies. For example, radar sensors are effective across most tank materials, whereas ultrasonic sensors might face limitations with materials that significantly absorb sound waves.

- Liquid Type: The properties of the liquid being measured play an important role in sensor choice. Viscous or foaming liquids, as well as volatile chemicals, might require options like radar or laser systems that remain unaffected by surface inconsistencies.

- Operating Environment: Consider the environmental conditions around your tank. Sensors operating in extreme temperatures, high pressure settings, or harsh chemical environments need to be designed to withstand these challenges.

- Budget Considerations: Non-contact sensors vary in price based on technology and features. Determine your budget while balancing it against your performance needs to select a cost effective yet reliable solution. Ultrasonic sensors are generally more affordable, while laser sensors often deliver premium precision at a higher cost, with radar sensors in the middle.

NTO Tank Support

Feeling unsure about which sensor to choose? The National Tank Outlet is here to help. Our team of experts provides personalized guidance to match you with the perfect sensor for your tank system. Whether you need advice on compatibility, technology selection, or the best option for your budget, we’re just a call or message away.

Takeaways

Non-contact tank level sensors are an important tool for accurate liquid measurement when physical interaction needs or is best to be avoided. They work using ultrasonic, radar, or laser technology to deliver precise, contamination free performance. With a range of types and suitable applications, these sensors offer unparalleled benefits in safety and reliability.

At NTO Tank, we pride ourselves on offering high quality, versatile tank monitoring solutions designed to meet the needs of various industries. Whether you’re managing agricultural systems, wastewater treatment, or chemical storage, we have the right sensor for you.

Explore our selection of non-contact tank level sensors. If you need help finding the ideal product for your setup, our knowledgeable team is ready to assist. Reach out to us today and upgrade your tank management efforts.