Storage tanks play a central role in a variety of industries, from holding chemicals in manufacturing plants to storing fuel in petroleum operations and managing wastewater in agriculture. While these tanks are essential for day-to-day operations, they also come with risks, such as leaks or spills, that can harm the environment, endanger workers, and disrupt business. This is where secondary containment comes into play. Acting as a backup barrier, secondary containment systems are designed to prevent harmful cargo from escaping into the surroundings in the event of a tank failure.

This article will explore when and why secondary containment tanks are needed, helping you understand their value in safety, compliance, and worksite operations.

Understanding Secondary Containment Tanks

What Are Secondary Containment Tanks?

Secondary containment tanks are an essential safety feature for industries that handle potentially dangerous or harmful liquid materials. They come in two main forms. Some storage tanks include built-in leak capture designs that add an internal barrier to prevent liquids from escaping. Others use external containment systems, such as separate structures that hold the primary tank and catch liquids in the event of leaks or failures. Both designs work to provide a layer of protection against potential risks.

The Purpose of Secondary Containment Systems

The primary goal of these secondary containment systems is to prevent liquid spills and leaks from spreading into the environment, workplace, or nearby properties. They are vital for industries that deal with hazardous chemicals, flammable substances, and even non-hazardous liquids used in industrial applications. By capturing leaks, secondary containment protects natural ecosystems, ensures the safety of workers, and helps businesses comply with environmental and safety regulations.

How Secondary Containment Tanks Work

Secondary containment tanks work as a safeguard that acts as a reliable backstop. If a primary tank experiences failure due to issues like corrosion, physical damage, or other malfunctions, the containment system captures the escaping liquid. This added layer of protection secures the liquid, preventing it from release and causing any harm. By offering this buffer zone, secondary containment systems give businesses and operators time to address the issue while minimizing damage or compliance risks.

With these systems in place, businesses can protect their operations, workers, and the local environment from costly and potentially dangerous leaks or spills. Understanding the purpose of secondary containment and how it works is a critical step for any business dealing with liquid storage.

Why Are Secondary Containment Tanks Important?

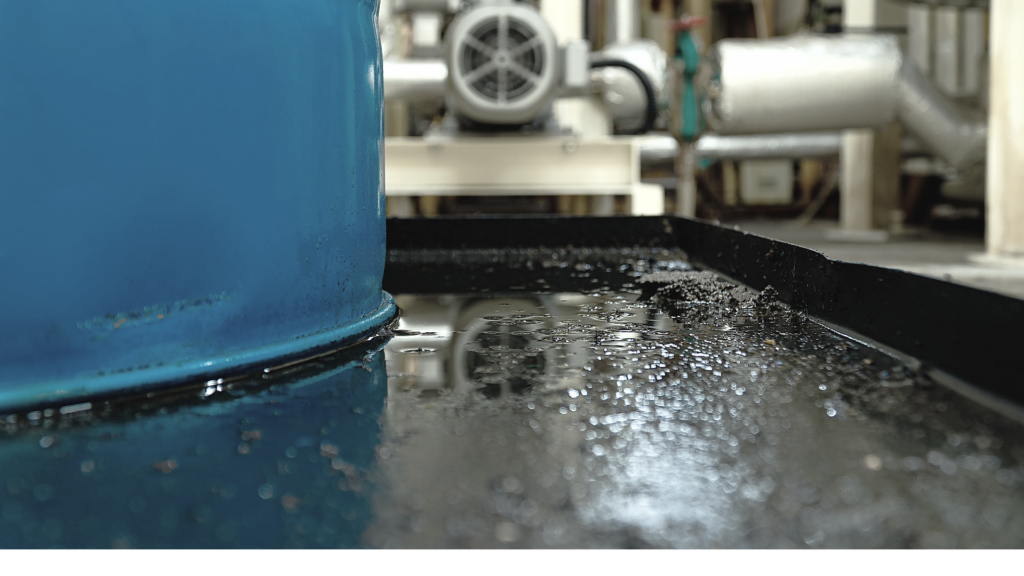

Environmental Protection

Leaks and spills from storage tanks can cause severe contamination to the environment that can impact soil, groundwater, and even air quality, which can affect many living things nearby. Secondary containment systems act as a safety net, capturing hazardous liquids before they can seep into the ground or surface water sources. For example, industries that store chemicals or petroleum products could prevent long lasting damage to ecosystems by employing these systems.

Real world examples include avoiding groundwater pollution from fuel storage tanks and safeguarding agricultural land from chemical runoff. By containing spills at the source, secondary containment tanks play a valuable role in preserving natural resources and avoiding the costly aftermath of environmental damage.

Worker and Public Safety

Hazardous material leaks don’t just harm the environment; they pose significant risks to workers and nearby communities. Secondary containment tanks help mitigate the potential for harmful exposure by ensuring that hazardous liquids stay confined. For example, in chemical manufacturing facilities, a containment system could prevent accidental chemical spills from endangering employees or spreading to surrounding equipment or areas where other chemicals may be stored.

Protecting the health of workers and ensuring safe worksites is paramount for industries that handle volatile or toxic substances. Additionally, secondary containment minimizes the risk of fires or explosions by safely isolating flammable liquids, which further protects public safety.

Continuous Operations

Spills and leaks can disrupt business operations, leading to costly downtime, regulatory fines, and damage to equipment. Secondary containment systems help businesses keep operations moving by providing a proactive solution to manage accidental spills. For example, a facility with an effective containment system in place can address leaks swiftly and avoid significant interruptions to their activities. Beyond just preventing fines and delays, such systems also protect asset integrity by reducing the risk of corrosion or other damage that can be caused by leaks. By securing operations against unpredictable events, secondary containment tanks support both compliance and business reliability.

Investing in secondary containment tanks isn’t just about meeting regulations, it’s also about safeguarding the environment, protecting people, and ensuring business success. Together, these points highlight their indispensable role across many different industries and use cases.

Regulations and Compliance

Key Regulations Governing Secondary Containment

Understanding the regulatory landscape is a key step in determining when secondary containment systems are necessary. Several federal and industry specific guidelines mandate the use of secondary containment tanks to prevent environmental harm, ensure workplace safety, and maintain regulatory compliance.

- EPA Regulations: The U.S. Environmental Protection Agency (EPA) plays a significant role in regulating facilities that handle oil or hazardous materials. According to the EPA, facilities must implement spill prevention measures to stop such substances from contaminating nearby soil, water, or air. The EPA requires appropriate secondary containment systems for bulk storage tanks to prevent spills or leaks from escaping the storage area.

- Spill Prevention, Control, and Countermeasure (SPCC) Rule: This rule, outlined in 40 CFR Part 112, applies to facilities storing large quantities of various oil or petroleum products. It mandates secondary containment for oil storage tanks that could reasonably be expected to discharge oil into navigable waters or shorelines. Specific requirements include creating containment systems capable of holding the capacity of the largest tank in the area, plus additional space for precipitation.

- OSHA Standards for Chemical and Hazardous Material Storage: The Occupational Safety and Health Administration (OSHA) sets certain regulations for storing chemicals and hazardous materials. OSHA’s secondary containment rules are triggered when individual primary containers exceed 55 gallons or when the total aggregate storage exceeds 100 gallons. Proper secondary containment must also include labeling, secure access, and material compatibility to ensure safety during leaks or spills.

- Industry Specific Guidelines: Many industries have custom or specific guidelines for secondary containment. For example, agriculture may require containment systems for large pesticide or fertilizer storage tanks. Similarly, the chemical manufacturing industry often follows strict protocols to ensure hazardous materials remain confined in case of a breach.

Consequences of Non-Compliance

Failing to comply with these regulations carries substantial risks that extend beyond environmental harm.

- Legal Penalties: Businesses may face hefty fines, citations, or lawsuits if they are found in violation of EPA, SPCC, or OSHA standards. This can lead to lengthy legal battles and increased scrutiny from regulatory bodies.

- Financial Impacts: Cleanup costs from spills can be extraordinarily high and potentially lengthy, not to mention the potential need for expensive upgrades to meet compliance after an incident occurs. Additionally, non-compliance can affect a business’s ability to continue operations, leading to loss in revenue.

- Reputational Damage: A company’s failure to follow safety and environmental regulations can hurt its reputation, alienating customers and stakeholders. Negative media coverage about a spill or compliance failure may deter potential business partnerships and lead to decreased market trust, which, for a business reliant on sales, can be highly detrimental.

Scenarios Where Secondary Containment Tanks Are Needed

Legally Mandated Situations

Certain facilities are required by law to incorporate secondary containment tanks.

- Facilities Storing Large Volumes of Hazardous Materials: Any site storing significant quantities of hazardous chemicals or petroleum products must adhere to regulatory requirements. For example, under the EPA’s SPCC Rule, all tanks with the potential to spill into navigable waters must include secondary containment systems sufficient to handle the full volume of the largest tank.

- Proximity to Sensitive Ecosystems or Water Sources: Facilities located near wetlands, rivers, lakes, and critical or sensitive ecosystems are legally compelled to protect these areas from potential spills. Secondary containment in such cases works to provide the necessary barrier that minimizes contamination risks from accidents.

High Risk Operations

Industries that handle volatile or challenging substances often turn to secondary containment tanks to serve as their critical safety measure.

- Handling High Pressure or Corrosive Materials: Applications involving aggressive chemicals, such as hydrochloric acid or caustic soda, require robust containment practices to address the increased risk of tank failure, leaks, or other hazards.

- Worksites with Adverse Weather Potential: Sites prone to flooding, heavy rainfall, or other severe weather events can experience challenges in managing runoff and drainage. Secondary containment tanks are indispensable in these scenarios, as they prevent leaks from compromising surrounding areas even during extreme conditions.

Proactive Risk Management

For some organizations, the decision to use secondary containment goes beyond the necessity of regulatory compliance to proactively seeking to manage future potential risks.

- Protecting High Value or Hard-to-Clean Products: Expensive chemicals, specialty oils, or products that are especially difficult to remove after a spill often prompt facilities to implement secondary containment tanks and are, indeed, good reasons to consider them as such systems protect against financial loss while simplifying maintenance tasks.

- Commitment to Sustainability: Companies that prioritize good environmental ethics often install secondary containment systems as part of their sustainability goals. These measures can stand as a testament of their dedication to reduce potential impacts on natural resources and promote long term responsibility.

Real World Examples

To visualize and provide context to these scenarios, consider the following:

- Chemical Manufacturing Facility Near a River: A chemical plant storing bulk acid solutions installed a lined modular secondary containment system to prevent accidental outflows or discharges into a nearby river. This setup enabled compliance with SPCC requirements and worked to preserve local aquatic ecosystems.

- Petroleum Storage Site in a Flood Zone: A fuel storage site in a region prone to tropical storms reinforced its tanks with additional containment measures to ensure that heavy precipitation would not overwhelm its spill management protocols.

- Specialty Oil Manufacturer with ESG Goals: A company producing high grade lubricants implemented secondary containment to strengthen its sustainability commitments. This step not only helped protect surrounding farmland but also improved the company’s reputation for environmental care.

Proactively or reactively, incorporating secondary containment tanks ensures businesses are ready and equipped to handle complex scenarios while safeguarding workers, communities, and the environment.

Types of Secondary Containment Systems

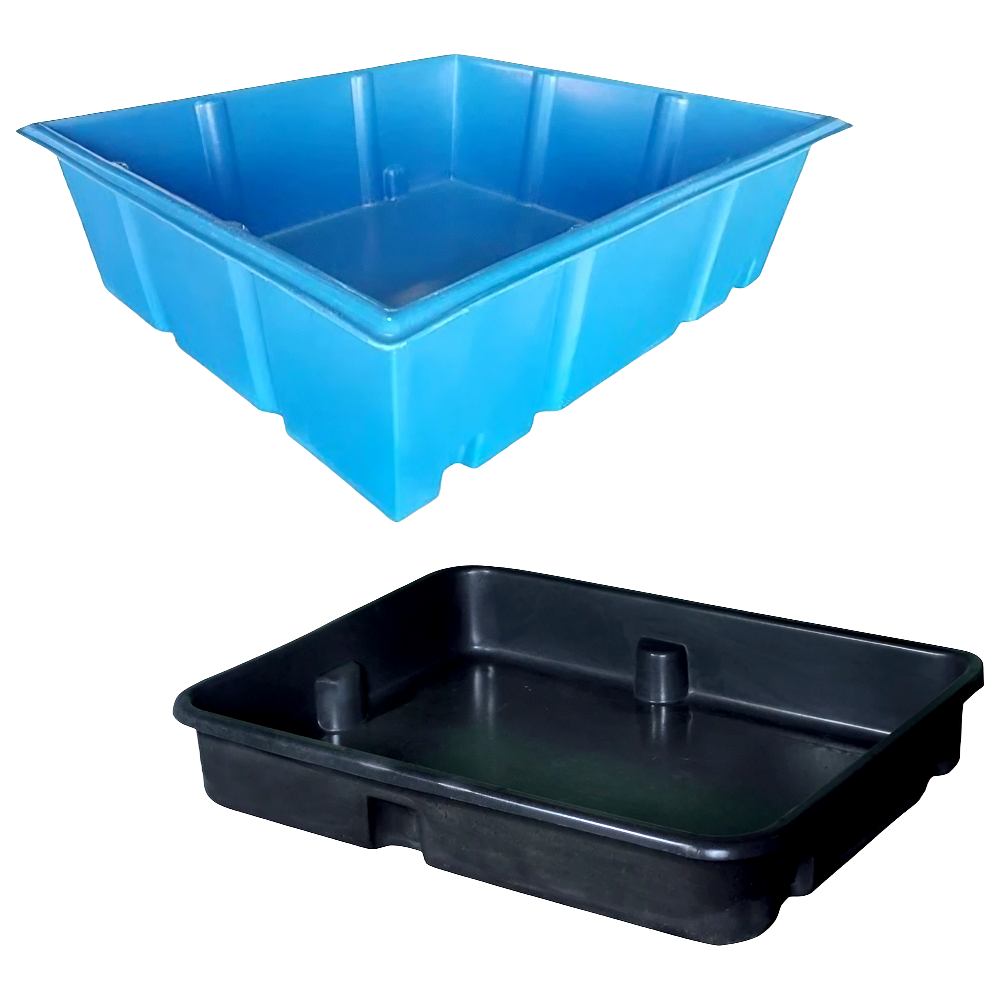

Integrated Secondary Containment Tanks

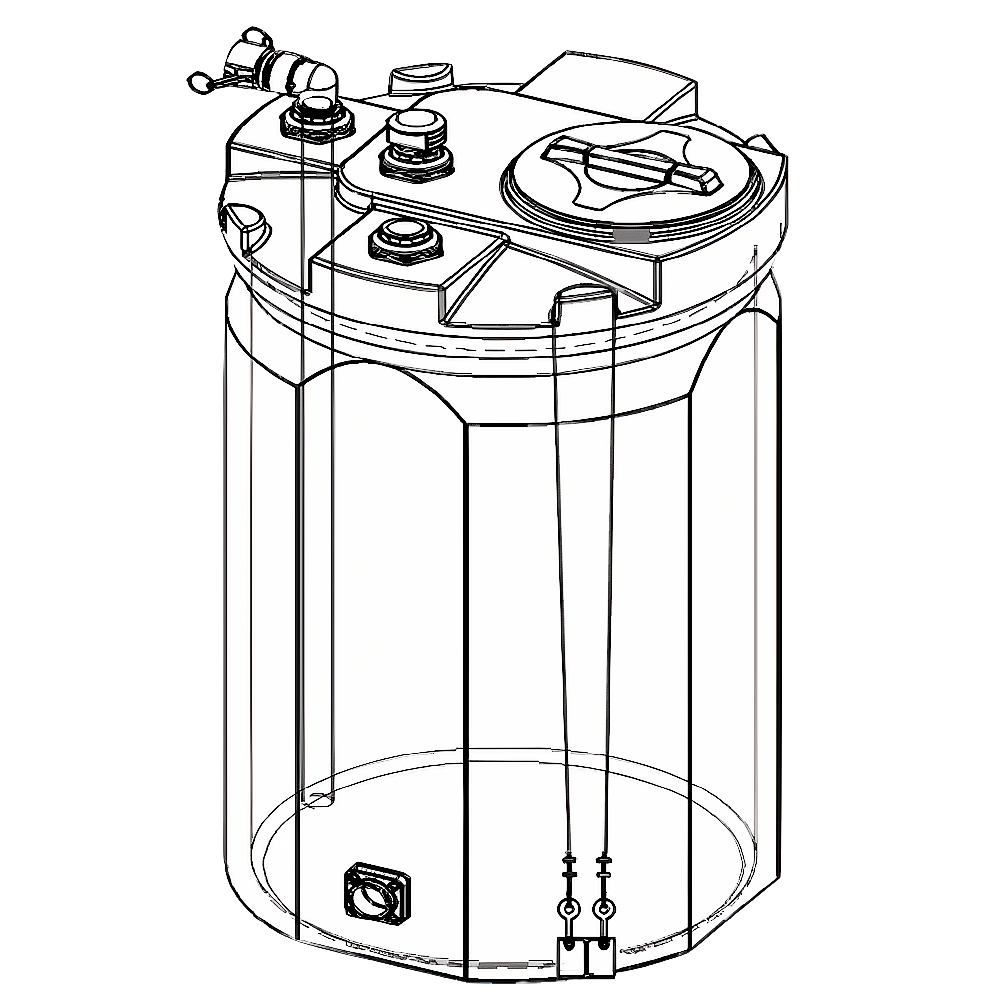

Fully integrated secondary containment tanks are designed with built-in features that enhance safety and minimize the risk of spills. These systems combine primary storage and secondary containment into a single unit that streamlines protection.

For example, Peabody Manufacturing Gemini Tanks feature double wall tank-in-a-tank designs that safely house chemicals, waste, or other liquids. The internal tank stores the cargo, while the external tank acts as a containment layer safeguard against leaks or failures that also ensure compliance with environmental regulations. These tanks are ideal for facilities that require compact, all-in-one solutions.

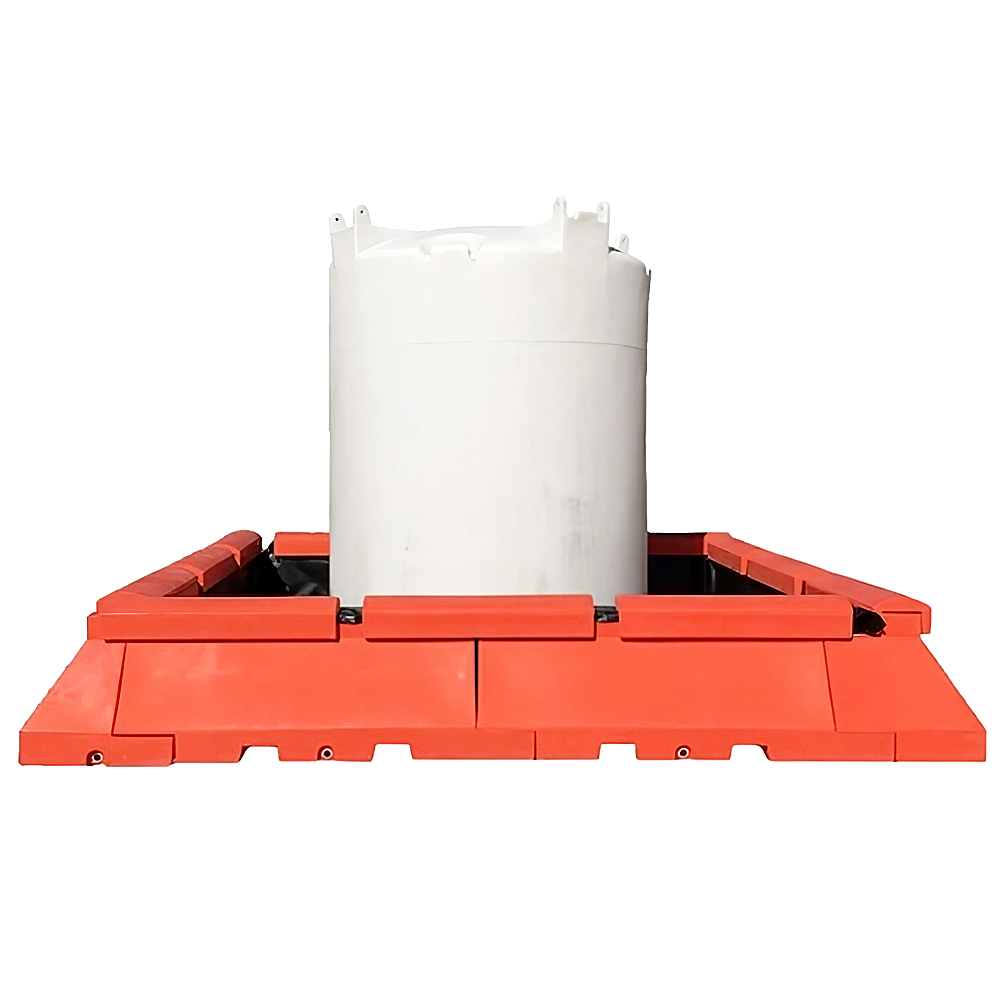

External Containment Systems

External containment systems include spill berms, dikes, barriers, and spill basins which are installed around primary tanks to contain potential spills. These systems offer flexibility and can be customized to fit specific layouts or tank sizes. External containment products, like NTO Tank’s secondary containment solutions, range from basic spill basins to modular setups designed to surround large capacity tanks.

Constructed from durable, weatherproof, chemical resistant materials, these systems are versatile and suitable for industries such as agriculture, manufacturing, and logistics. Modular solutions, in particular, allow for rapid on-site assembly and are ideal for expanding containment as storage needs grow.

Double Walled Tanks

Double walled tanks take redundancy in safety to the next level with a “tank within a tank” design. The inner tank houses the main liquid, while the outer tank serves as the secondary containment layer. This dual-wall structure ensures that any breach or leak in the inner tank is immediately caught by the external layer, greatly minimizing the risk of spills.

Available in high density polyethylene (HDPE) or cross link polyethylene (XLPE), NTO’s double walled tanks are highly effective for storing chemicals, fertilizers, and toxic liquids in both indoor and outdoor environments. Additional features like leak detection sensors and insulation options make these tanks an excellent choice for facilities that prioritize safety and reliability.

Best Practices for Implementing Secondary Containment Systems

Risk Assessment

A thorough risk assessment is the foundation of an effective secondary containment strategy. Start by fully evaluating the site and considering details such as proximity to sensitive ecosystems, local drainage patterns, and regular weather conditions. Understand the risks posed by the specific materials being stored — for example, chemicals with high corrosivity or reactivity demand more robust containment solutions. Identifying potential vulnerabilities allows for targeted measures that can greatly reduce the likelihood of spills and avoid potential impacts on the surroundings.

Material Compatibility

The effectiveness of a secondary containment system hinges on its ability to withstand the substances it is designed to store. Ensuring material compatibility is essential. Containments made from improper materials may degrade over time of exposure, increasing leak risks instead. For example, high density polyethylene (HDPE) is suited for many chemicals, while other substances may require polypropylene, cross linked polyethylene, or specialized coatings. Always consult with manufacturers and review chemical resistance charts to select the appropriate product material for your containment needs.

Proper Installation and Maintenance

Correct installation will ensure the functionality of a secondary containment system. Poorly installed systems may fail under pressure or environmental stresses. Following the manufacturer’s guidelines and employing skilled technicians is the best way to prevent future issues. Also, regular inspections and maintenance will help to identify and address minor damages before they worsen. Repairs and upgrades should align with evolving safety standards and work needs to maintain overall integrity and regulatory compliance.

Employee Training

Your containment system is only as reliable as the people managing it. Employees should be trained to recognize early signs of wear and tear, understand inspection and maintenance schedules, and how to respond effectively to spills. Routine training sessions will promote staff preparedness and reinforce their roles in both daily operations and emergency scenarios. Knowledgeable employees can prevent incidents through vigilance and prompt action.

Emergency Response Plans

Even with heavy duty secondary containment measures, it’s essential to be prepared for worst-case scenarios. Develop and implement comprehensive emergency response plans tailored to your facility’s specific risks. These protocols should include clear instructions on containment, cleanup, evacuation, and notification procedures. Regularly review and update the plans to address any changes within the facility or regulations. Conduct drills to ensure all staff are familiar with their roles during an emergency as well as improve the effectiveness of the response effort.

Cost Considerations

Balancing Costs vs. Potential Savings

Investing in a secondary containment system may seem like an upfront expense, but the potential savings far outweigh the costs. Facilities without proper containment measures risk significant financial penalties for non-compliance with regulations. Beyond fines, the costs of managing environmental cleanup, product loss, and rebuilding public trust after a spill can be astronomical. A single spill event into a sensitive ecosystem could trigger expensive remediation measures, litigation, and reputational damage. By comparison, secondary containment systems act as an insurance policy that protects financial resources and the overall integrity of business operations.

Understanding Lifecycle Costs

Secondary containment systems are more than one-time investments — they are a long term strategy for both safety and efficiency. Initial purchase and installation costs are only a part of the equation. Facilities must also account for periodic maintenance, inspections, and potential upgrades. Fortunately, high quality containment systems are engineered for strength and long service lives, which reduces how often they need replaced and ensures compliance without the need for constant intervention. Over time, the cost of proactive compliance is overshadowed by the benefits of avoiding accidents, maintaining operations, and environmental protection.

Closing Thoughts

Secondary containment tanks are an essential part of industrial operations across many industries. They provide critical protection against spills and leaks, mitigating risks that can threaten workers, communities, and ecosystems. Beyond safety and compliance, these systems reflect a company’s commitment to environmental stewardship and responsible operations.

Every facility has unique needs, and implementing the right containment solution requires careful assessment and expert guidance. By considering your materials, risks, and operational goals, you can select the system that best suits your requirements and ensure full compliance with regulations while achieving the long term benefits.

For those ready to take the next step, consulting with specialists and exploring the range of secondary containment products can provide clarity and direction. Addressing these needs proactively not only prevents costly incidents but also positions your business as a leader in safety and sustainability.

Begin evaluating your containment requirements today and explore the products offered by the National Tank Outlet that match your operational and compliance goals.

FAQs

How do I know if my facility requires secondary containment?

Facilities that store hazardous or regulated materials, particularly in large volumes or near sensitive environments, are often required to implement secondary containment measures. Consulting local, national, and industry specific regulations, like the EPA’s SPCC Rule, can help determine your specific obligations.

Can secondary containment solutions be retrofitted to existing tanks?

Yes, retrofit solutions such as external spill berms, liners, or modular containment systems can be installed around existing tanks to enhance safety and compliance. Always ensure that retrofits meet regulatory standards and compatibility for performance.

What factors affect the choice of a containment system?

Key factors include the type and volume of the liquid materials being stored, site specific risks (e.g., weather, proximity to water bodies), regulatory compliance requirements, and budget considerations.