To define rainwater harvesting: rainwater harvesting is the practice of capturing rainfall and using it as an alternative water source for water-requiring activities around or inside a property.

In this Rain Tanks Series: Rainwater Harvesting 101, we will look at a nearly inclusive overview of the rainwater harvesting practice, definition of terms, regularly used equipment, and consider the difference between active and passive systems.

Harvesting rainwater is either active or passive in practice and can also be known as rainwater catchment, rainwater collection, abbreviated RWH, and setups are known as rainwater harvesting systems, which can be abbreviated RHS for short.

Active vs Passive Rainwater Harvesting

Active rainwater harvesting is the practice of directing the rain from the surface it lands on and into a container for storage where the water can be collected, increase in volume, and then used whenever needed by the owner. Active rainwater harvesting often involves a roof, gutters, a rain tank or rain barrel, accessories such as debris filters and first flush diverter, PVC pipe or hoses, and possibly a water pump.

Passive rainwater harvesting is many times practiced without a storage container and is done when rainfall is channeled from a surface directly to a point of use, such as a pond, rain garden1, landscaping, or low spots on a property.

Between active and passive, active rainwater harvesting is more common and the method most rainwater harvesters choose to practice. Both RWH practices seek to manipulate precipitation2 to achieve a source of water, prevent erosion, reduce runoff contaminants, and better the collective environment. The main benefit and difference of active rainwater harvesting is it allows water to be stored and used when wanted for exactly what is needed.

Uses for Rainwater

- Water gardens, house plants, and food plots

- Sprinklers and landscape irrigation systems

- Fill ponds and other landscape water features

- Fill pools and maintain water levels

- Wash vehicles, equipment, and machinery

- Supplement well water supply

- Provide drinking water for livestock, pets, and wildlife

- In agriculture for irrigation, pasture care, animal care, processing, cooling, and cleaning

- Aquaculture applications

- Hydroponic and aquaponic growing

- Fire suppression systems and fire fighting

- Emergency water supply during disasters and survival scenarios

- Reduce and manage stormwater runoff

- Non-potable uses both inside and outside such as flushing toilets and irrigation3 at homes, businesses, and public buildings

- Complete water use in homes and businesses including flushing toilets, appliances, sinks, showers, and bathtubs (dependent on local regulations4 and proper system setup)

Benefits of Rainwater Harvesting

- Water conservation, with potential for wide-reaching effects across society and the environment

- Reduce the volume of groundwater withdrawals

- Reduce use or reliance on municipal or main water supply

- Save money by lowering water bills

- Healthier, better-quality water for plants, crops, and animals as rainwater is naturally soft, free of groundwater minerals and water treatment chemicals

- Reduce soil erosion, especially in arid environments and landscaping around structures

- Reduce downstream flow of pollutants5 such as fertilizers, pesticides, human waste, and roadway contaminants

- Stormwater management and reduction

- Potential for use in groundwater recharge

- Potential for increase in property value

The 3 C’s of Rainwater Harvesting | What is Needed to Harvest the Rain

To be a successful rainwater harvester, you will need, at least, a catchment area, a conveyance system, and a collection container. These are known as the 3 C’s of Rainwater Harvesting: catchment, conveyance, and collection. Other rainwater accessories and equipment may be recommended or needed depending on how clean, efficient, and overall effective of a RWH system is wanted.

Catchment Areas

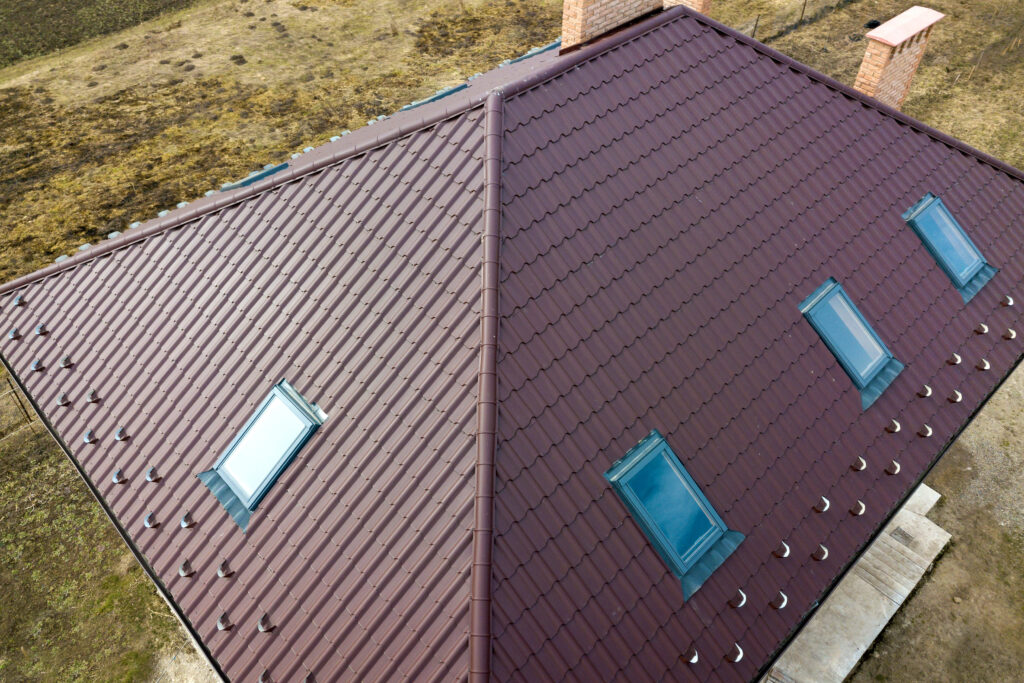

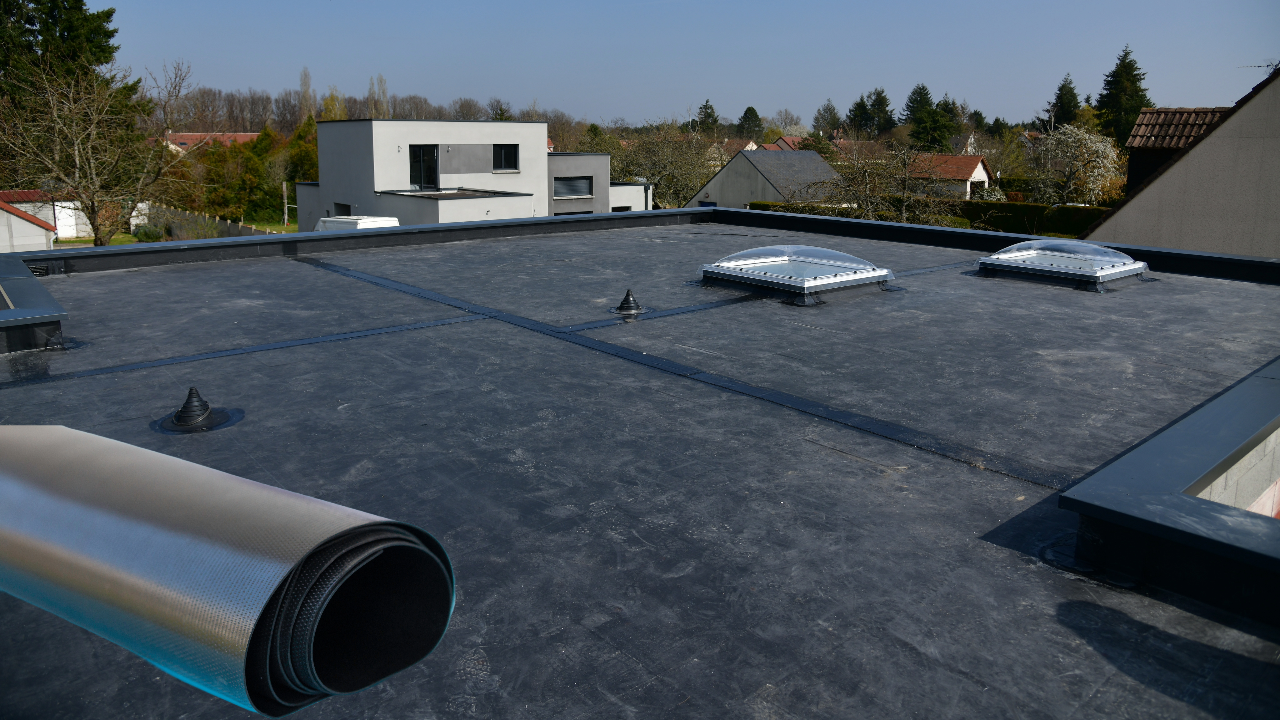

In rainwater harvesting, the term Catchment Area refers to the surface that the rain falls on and is used to collect rainwater from. A catchment area6 can be any surface that allows rainwater to easily flow over it without being absorbed and from where the rain can be directed to the point of collection or use.

Catchment areas are most often the roof of a building, and most commonly the roof of a home or business. The roofs of sheds, pavilions, garages, warehouses, equipment yards, barns, greenhouses, and livestock houses are other common rainwater harvesting catchment areas. Non-roof type catchment area examples include pavement such as parking lots, streets and roadways, tarps, rocky surfaces and outcrops.

The best catchment area for rainwater harvesting7 is any impervious surface that rain will not soak into. The best material to catch rainwater will not contribute debris, leach any chemicals, will resist growth of moss or mold, can be cleaned, and easily washes away any foreign debris that has accumulated on the catchment surface. Seam metal roofing made from finished steel is the top recommended material and best choice for a rainwater catchment area. The second-best choice are slate tiles, followed by composition shingles, FDA approved EPDM coated roofs, and lastly asphalt shingles.

Asphalt shingle roofs are the most common and the roof type installed on most residential homes. They are the least recommended option as they can leach chemicals over time or contribute small pieces from the shingles into the rainwater.

Conveyance Systems

In rainwater harvesting, the term Conveyance System refers to any object or series of objects that can be used to channel rainwater as it flows from the catchment area to the collection container or containers. A conveyance system8 should be able to successfully contain, control, and direct rainwater without leaking or contaminating the water. Conveyance systems are most often gutters, downspouts, and plumbing such as PVC pipe.

Gutters and downspouts are a common choice as they are typically already installed on buildings to direct rainfall away from the structure’s foundation. Gutters and downspouts can be easily modified for use in a RWH system and customized with rain harvesting accessories. PVC (vinyl), aluminum, and galvanized steel are the preferred guttering material types.

Plumbing such as PVC pipe is the most recommended9 and often used to replace downspouts or used to extend the reach of the conveyance system. Plumbing is used when the rain collection container cannot be placed directly next to a building, when multiple downspouts are to be connected, to connect multiple tanks together, and to connect the RWH system to additional equipment or fixtures for use.

When shopping for PVC pipe to use in rainwater harvesting, it is recommended to use ANSI/NSF 61 and/or ANSI/NSF 14 certified PVC pipe10. This type of plumbing is approved to handle potable water and will not impact the quality of your rainwater harvest. This recommendation stands even if the rainwater is not intended for potable applications.

Pre-Tank Filtration

Pre-Tank Filtration refers to rainwater harvesting accessories that are installed in the system before the collection container and are used to improve the cleanliness of the rain by removing debris and some contaminants. Examples of pre-tank filtration include downspout screens, first flush diverters, and tank screens. Pre-tank filtration is used to provide cleaner, higher quality rainwater as it is being collected. The cleaner the rainwater harvested is, the less overall amount of system maintenance required11.

A downspout screen, also known as a leaf eater or rain head, is one of the more commonly used pre-tank filtration accessories. They are built with an open top, fine mesh screen, and bottom port connector designed to screen out and remove unwanted debris while allowing rainwater to flow through. Downspout screens can only be used to remove large debris12 such as sticks, leaves, other plant matter, animals and insects.

Downspout screens are often used as they are easy to install, simple in design, and effective. They are made for placement within the downspout of the RWH conveyance system.

A first flush diverter is also a common rainwater harvesting accessory added to improve the quality of collected water. The first flush diverter is also known as a roof washer. It is used to collect and flush away some of the first rainwater during a rain event that washes debris from the roof and is therefore often the dirtiest and most contaminated. This accessory can be used to remove materials that a downspout screen cannot13 remove such as sediment, animal droppings, pollen, any potential chemicals or other finely sized materials.

A first flush cannot be used exclusively to completely remove and prevent some dissolved contaminants from reaching the rain container for drinking quality water. For full details on the first flush diverter, functions, options, and use, see our post First Flush Diverters Explained.

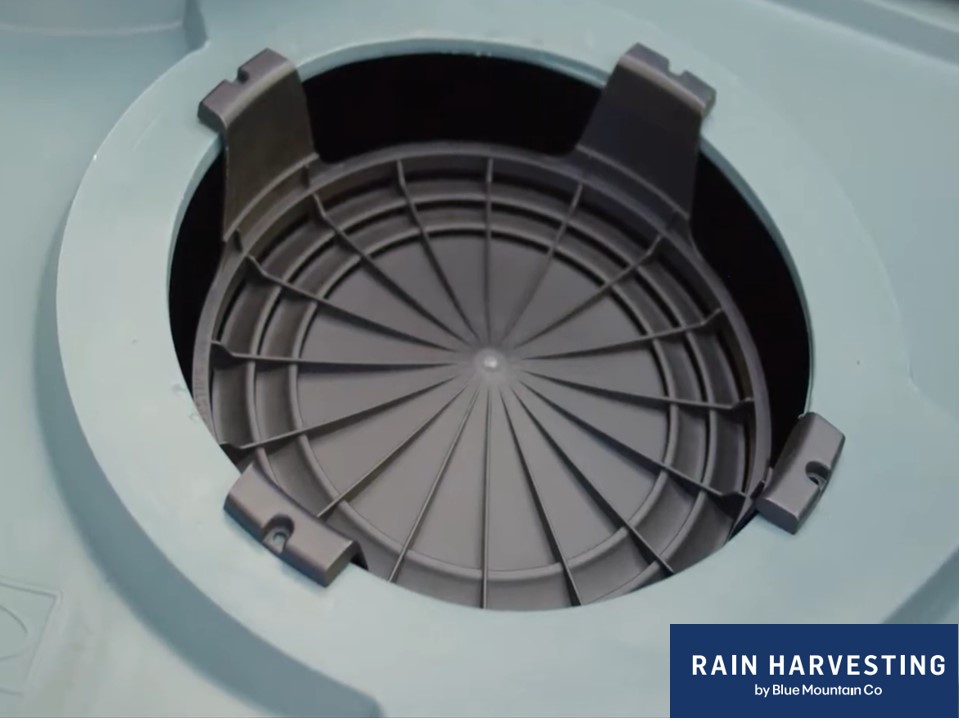

A tank screen is a fine mesh basket filter. The accessory is made to fit in the manway opening on bulk volume rainwater tanks and catch debris immediately before it reaches the container. A tank screen comes standard with many polyethylene rain tanks when purchased and is effective in removing large debris and anything that another pre-tank filtration accessory may have missed.

When all three pre-tank filtration accessories are used together in a rainwater harvesting system, the chances for debris, unwanted materials, insects or animals reaching your collection container becomes much more unlikely and the overall general quality of harvested rainwater becomes much cleaner.

Collection Containers

The Collection Container is the most important part of an active rainwater harvesting system. Without it, every gallon of rainfall will go to the soil rather than be captured for use. Rainwater collection containers are available in many types14 and include rain barrels, polyethylene rain tanks, underground poly cisterns, galvanized steel rain tanks, stainless steel rain tanks, and IBC totes. All of these container types are commonly used in the practice of rainwater harvesting and are available for purchase.

Rain harvesters will choose one container type over another based on the total water volume they need, what the rainwater will be used for, available property space, and budget limitations.

Types of Rainwater Containers

- A rain barrel is smaller in size and volume capacity, often ranging from 50 gallons up to 100-150 gallons. Rain barrels are ideal for small volume needs, outdoor uses, properties with limited space, and those looking to harvest rainwater on a budget.

- A polyethylene rain tank has a wide range of sizes and storage volume, often ranging from 100 gallons up to 10,000 gallons. Polyethylene rainwater collection tanks are ideal for long term reliability, are lightweight, low in cost compared to metal, and are suitable for all rainwater harvesting applications.

- An underground poly cistern has a rainwater storage range up to 20,000 gallons. Poly underground water tanks are ideal for long term use, properties with limited aboveground space, and when the benefits of underground installation are desired such as protection from freezing temperatures and algae.

- A galvanized steel rainwater tank is often the choice for storing very large volumes of rainwater in a tank capable of lasting for decades. Having a volume range up to 100,000 gallons or more, galvanized steel rain tanks provide one of the largest storage volumes available, but also have a higher purchase price and most often require professional installation.

- A stainless steel rain tank is made from high quality metal and can last a lifetime, but due to the material, stainless steel rain tanks are often a more expensive option and one with a lower total available volume range.

- An IBC tote is a shipping, storage, and application container popularly repurposed and used in DIY for rainwater harvesting or other alternative projects15. The polyethylene caged IBC tote with 275 gallons or 330 gallons capacity are the common choice for RWH systems. IBC totes are popular as they provide a large volume with a lower cost, are lightweight, easy to modify, and can be purchased secondhand16 or as a rebottled IBC tote for less.

Additional Points on Collection Containers

In rainwater harvesting, a collection container can be any watertight vessel made of any material to any shape and volume size. It is simply important to ensure the container’s material, shape and volume match the needs of the use and layout of the property.

The material the rain container is made from should be safe to store rainwater17 long term, should not leach chemicals into the rainwater, should not break down, rust, leak, or rupture. The most common materials used for rainwater collection containers are polyethylene plastic and metal. Earthen materials such as concrete are also sometimes used.

The collection container should also be kept closed, vented, and include fine mesh screens at every opening to prevent access by animals and insects such as mosquitoes. Preventing mosquitoes from breeding in your rain tank is an important and responsible measure for all rainwater harvesters18 and is even required by local regulations in some areas of the United States.

Most bulk volume rainwater collection containers commercially available for purchase are designed and made from materials that cover these points to ensure the container is safe, reliable, and approved for water handling. Our polyethylene plastic rainwater containers are both made using U.S. FDA approved materials and are NSF/ANSI 61 certified for potable water applications.

Improvement Accessories for Rain Containers

RWH Collection Container Improvement Accessories are tank add-ons made to improve storage effectiveness, water quality and reduce maintenance. Examples include the solar shield, tank screen cover, and water level gauge.

The solar shield is a dual-function accessory designed to inhibit the amount of sunlight that reaches the stored rainwater through an open manway and also acts as a calming device and water brake to slow the inlet of rainwater as it flows into the tank. A solar shield will help to prevent algal growth and the resuspension of sediments.

The tank screen cover is exactly as it sounds: a cover for the rain tank screen. A tank screen cover is a lid that fits over a tank screen filter to completely block out sunlight while still allowing rainwater inflow through plumbing port holes built into the cover. Limiting sunlight is an important step in reducing algae in a water tank.

A rainwater tank gauge is used to allow an owner to easily see and monitor the current water volume in their collection container without having to open and look inside the tank. Common rainwater tank gauges are mechanical, non-electrical volume gauges that use a float and/or weight balance system that changes the reading on the tank gauge as water levels in the tank change.

Water Pump

A water pump is a specialized piece of equipment, often electric powered, that is used in rainwater harvesting to increase the speed and force strength of water as it is being drawn from the collection container.

Speed refers to how fast the water moves through a pipe or hose and is listed on water pump products as flow rate in gallons per minute (GPM). Force strength refers to how much output power the water will have and is listed on water pumps as pressure in pounds per square inch (PSI). A water pump can have a high flow rate with a low pressure output, and vice versa.

Water pumps are made in a variety of designs and capabilities. They are optional for many personal rainwater harvesting systems but are required for many specific applications.

A water pump is used in rainwater harvesting to increase the rate that water is withdrawn from the collection container for filling activities, to increase water pressure for equipment use, or both. To use rainwater with a higher pressure sprinkler, spray irrigation system, spray nozzle, or with post-tank filtration and treatment equipment, a water pump will be necessary.

If harvested rainwater will be used indoors, a water pump will be needed to provide enough water flow and pressure to taps and appliances for them to properly work.

Post-Tank Filtration

Post-Tank Filtration refers to rainwater filtration, purification, and/or treatment equipment positioned after the collection container in the RWH system and before the point of use. Post-tank filtration is used to clean and/or purify rainwater for higher quality applications such as indoor uses. Rainwater should not be used for drinking without treatment due to potential contaminants19. Similar to a water pump, post-tank filtration may not be necessary depending on the use and is only needed for specific rainwater applications such as drinking water or purified water for equipment.

Examples of post-tank filtration include sediment filters, carbon filters, multi-stage cartridge filters, ultraviolet (UV) light water treatment systems, chemical dosing systems, ozone generators, and direct chemical treatment.

Post-tank filtration options will require the addition of a water pump in all instances for proper equipment operation except for chemical dosing systems, ozone generators, and direct chemical treatment with chlorine (bleach / sodium hypochlorite).

To achieve potable (drinkable) rainwater from harvesting, the recommendation is to use an ANSI/NSF 53 certified multi-stage cartridge filtration unit with sediment and carbon filter rated down to a 5-micron pore size and an ANSI/NSF 55 certified Class A ultraviolet light treatment system20. For more info on making rainwater safe to drink, see our blog post here.

Takeaway | Rainwater Harvesting 101

It is our hope this guide to rainwater harvesting has helped with an overview of the rainwater harvesting practice, provide definitions and examples of the common components required to successfully harvest rainwater, and has helped in whatever step or stage you are at in planning, preparing or implementing your own rainwater harvesting setup.

We have a wide selection of rain harvesting accessories and rainwater collection tanks available for implementing a full-scale effective and efficient rainwater harvesting system. If you require any assistance in selecting the equipment you need, reach out to our product experts who will be glad to help.

Rainwater Tanks & Barrels