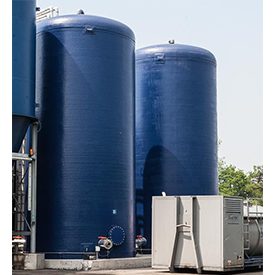

Fiberglass Water Tanks

Store Potable and Non-Potable Water Safely & Securely

We offer a complete line of fiberglass underground and above ground water storage tanks for use in rainwater collection, storm water runoff, and storage systems for both potable and non-potable water. Potable water tanks are built to ASTM D3299 and AWWA Standards using NSF approved resins with UV inhibitors to ensure durability, and above ground tanks are coated to your specifications.

Whether you are collecting rainwater for immediate use or storing it for a later time, collected water has many uses including indoor, outdoor, and storing for water emergencies. Underground and above ground rainwater tanks are available and custom-fitted for your rainwater collection needs. These high-quality tanks are built to ASTM 4097, ASTM D3299, and AWWA Standards, as well as are maintenance and corrosion free.

As concerns continue to grow about water shortages in many parts of the United States, municipalities and facility owners continue to search for ways to better manage their water resources. The versatility of fiberglass tanks make them ideal for commercial fire protection applications because they can be designed for dual-purpose use, with a common example being fire protection standby as well as potable water.

Leak-free performance is essential when it comes to waste water storage. Built using only superior corrosion-resistant resin, fiberglass wastewater storage tanks will not degrade with infiltration and exfiltration, and is non-reactive to sewer gasses. With high tensile strength and flexibility with many customizable options and simple transport and installation, fiberglass tanks are an easy choice for wastewater storage.

As climate change begins to have a greater impact on our day to day lives, by conserving water in drought prone areas with irrigation tanks, you are able to store much needed water for times when mother nature does not provide. By storing rainwater you could potentially save your crop or valuable livestock. Oil steel silos are being replaced with new fiberglass tanks that are stronger by weight and much more suited for rural flat lands where the environment is more demanding.

Fiberglass tanks built to ASTM D3299 standards and designed spcifically for the application material of choice for high performance briners. Fiberglass briners continue to be the most utilized material of construction. We are capable of utilizing FDA food grade and NSF 61 approved resins and materials for any tank diameter and capacity.

The Horizontal tank ends are domed or dished to provide a better distribution of weight and added strength. The horizontal fiberglass tank can be mounted on carbon steel, concrete or polyurethane foam filled cradles are considered standard on fiberglass tanks. They are glassed to the tank.

Fiberglass tanks have a long history of use in applications where watertight design integrity is critical. Vertical flat bottom and vertical leg fiberglass tanks can be open tops or can be enclosed with dome, dished or conical top. Vertical leg fiberglass tanks can also be fitted with dome bottoms with a 30" clearance, as well as a cone bottom. Smaller tanks are built with angle iron legs while larger tanks have l-bean legs.

For industrial and commercial needs, fiberglass sectional tanks can be erected on location. Sectional tanks are manufactured at the plant and transported to the job site. All appurtenances are field installed by experienced field crews, who have over ten years of experience installing sectional fiberglass tanks.